Stepping into the world of 3D printing can sometimes feel like being thrown into a labyrinthine maze, with an array of options and choices that seem mind-boggling. This comparison guide will unravel the mysteries surrounding two popular motor drivers: TMC2209 and TMC5160. Just as secret passages hold hidden treasures, these two drivers hold unique features and functionality that set them apart. So, grab your map and let’s embark on this exciting journey to discover the difference between TMC2209 and TMC5160, and find the perfect fit for your 3D printing adventures.

What is a stepper driver?

Stepper motors are becoming increasingly popular in 3D printing applications due to their ability to move precisely and accurately in tiny increments. 3D printer manufacturers have also been taking advantage of the stepper driver’s features to design their own custom motor controllers, which provide users with improved performance. Stepper drivers are also being used for laser-cutting machines, CNC routers, and other automated machinery.

For those who are interested in learning more about stepper drivers, there are plenty of websites and forums online where users can find more information. Additionally, the manufacturer’s website is always a great source for technical specifications and other useful information. With its superior precision and versatility, it’s no wonder why stepper drivers are becoming an essential part of many engineering projects [1].

What Are the Differences Between TMC5160 and TMC2209?

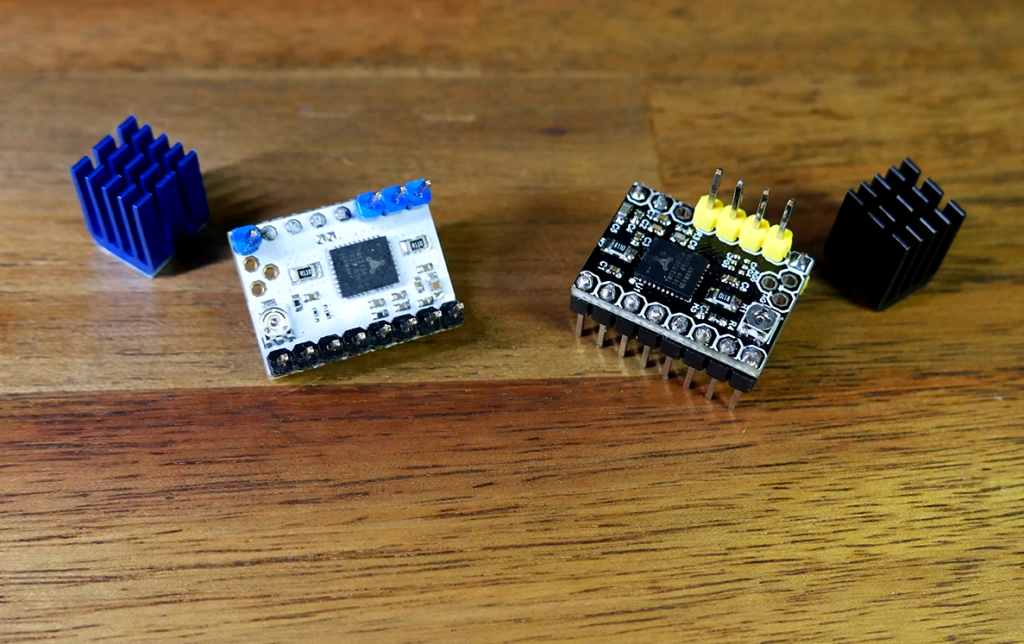

Maximum Phase Current

One of the key distinctions between the TMC5160 and TMC2209 lies in their maximum phase current capabilities. The TMC5160 boasts an impressive maximum phase current of up to 3.2A rms (root mean square), while the TMC2209 offers a slightly lower maximum phase current of up to 2.8A rms. This disparity means that in scenarios demanding higher currents, the TMC5160 exhibits a superior performance, delivering a more robust and powerful output compared to the TMC2209. This significant difference in maximum phase current capacity makes the TMC5160 an ideal choice for applications requiring enhanced power and efficiency.

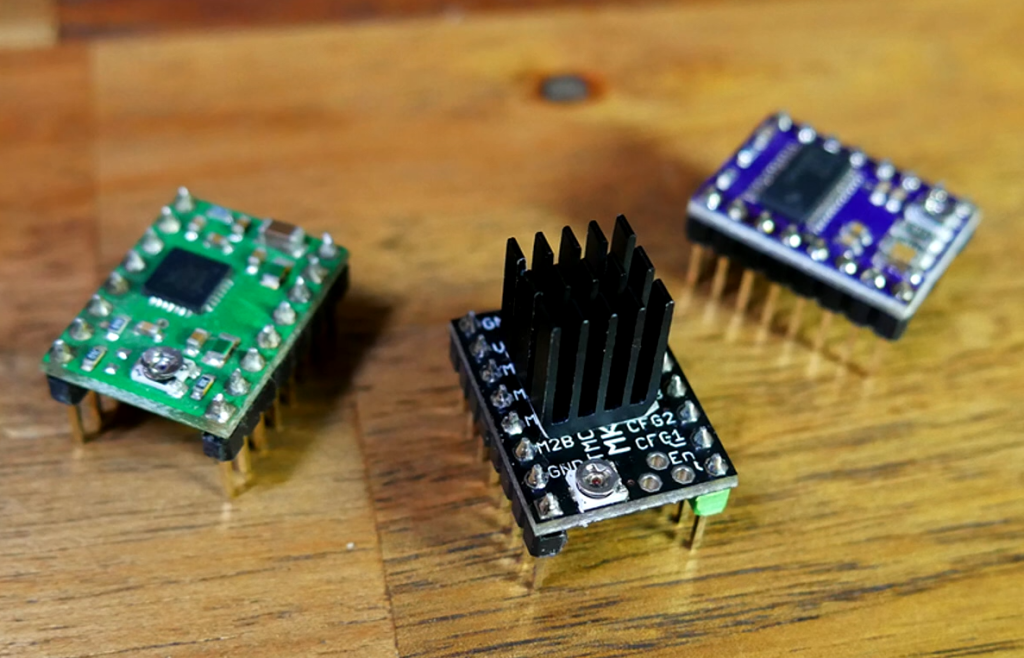

Cooling System

Another significant difference between these two stepper motor drivers is the type of cooling system they employ. The TMC5160 stands out with its advanced cooling technology, incorporating both active and passive cooling systems. This comprehensive cooling approach allows for optimal heat dissipation, ensuring efficient operation and minimizing the risk of overheating or malfunctioning.

On the other hand, the TMC2209 relies solely on an active cooling system. While it still provides adequate cooling, it may not match the superior heat transfer capabilities of the TMC5160, especially during extended periods of operation at higher currents. Therefore, for applications that demand prolonged usage under higher current loads, the TMC5160 emerges as the superior choice due to its enhanced cooling capabilities and improved performance.

RDSon

The TMC5160 and TMC2209 differ in their respective RDSon or “on-resistance”. The TMC5160 boasts an RDSon of 0.45 Ohms, while the TMC2209 has a slightly higher RDSon of 0.60 Ohms. This subtle disparity in RDSon values leads to significant distinctions in efficiency and power. With its lower RDSon, the TMC5160 demonstrates greater efficiency and power, thereby delivering a more optimized performance compared to its counterpart. This exceptional performance makes the TMC5160 an ideal choice for applications that require high torque at low speeds, ensuring exceptional functionality and precision.

Communication Protocols

The TMC5160 and TMC2209 both use the SPI (Serial Peripheral Interface) communication protocol, allowing them to be connected to external devices such as microcontrollers, computers, and other peripherals. The main difference is that the TMC5160 also supports UART (Universal Asynchronous Receiver/Transmitter) communication protocols. This allows for an easier connection between the TMC5160 and other external devices, as well as providing a means for more complex communication between them.

Special Features

The TMC5160 offers a few extra features that are not present in the TMC2209. These include an integrated rotary encoder for improved positioning accuracy, support for a range of motor types from NEMA 17 to 23, and adjustable current settings. The latter allows users to set the maximum motor current according to their particular application requirements, giving them greater control over the motor’s performance. The TMC2209, on the other hand, does not offer these features, making it a less suitable choice for applications that require more precise operation [2].

How to Choose Between the TMC5160 and the TMC2209 Stepper Drivers?

Choosing between the TMC5160 and the TMC2209 stepper drivers can be a difficult decision. Depending on your application, there are several factors to consider when selecting the right driver for your needs.

First, you should consider the type of motor you’re using. The TMC5160 is designed for stepper motors that require higher currents than the TMC2209. If you’re using a high-current motor, such as a NEMA 23 or larger motor, then the TMC5160 is likely the better option.

Second, consider your speed and torque requirements. The TMC5160 is capable of higher speeds and greater torques than the TMC2209, so if you need faster speeds or higher torques, then it is the better option.

Third, consider your budget and other cost considerations. The TMC5160 is more expensive than the TMC2209, but if you need superior performance, then it may be worth the additional expense.

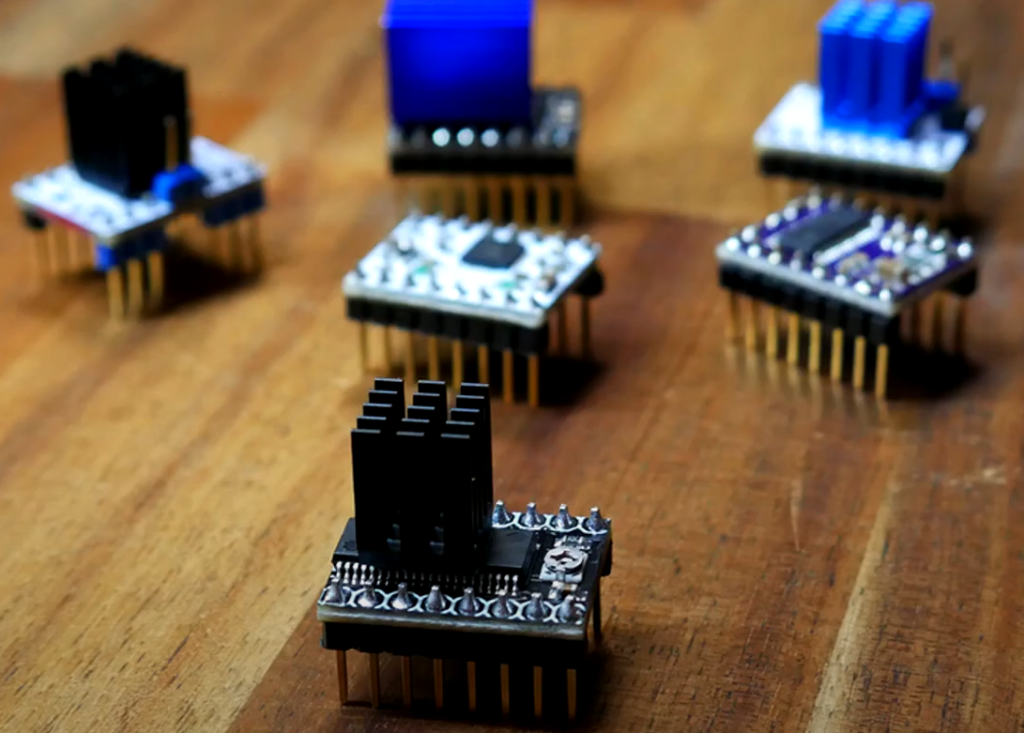

Finally, consider your installation requirements. The TMC5160 requires a heat sink and active cooling, while the TMC2209 does not. Depending on your application, this could be a deciding factor in which driver to choose.

Overall, the TMC5160 and the TMC2209 both offer excellent performance for their respective applications. By considering your motor type, speed and torque requirements, budget, and installation requirements, you should have an easier time deciding which driver is right for you.

When selecting a stepper motor driver, you should also make sure that you are choosing one with features such as current overvoltage protection, sensorless stall detection, and adjustable micro stepping resolution. These features can help ensure that your motor runs smoothly and efficiently, regardless of the type of driver you choose to use.

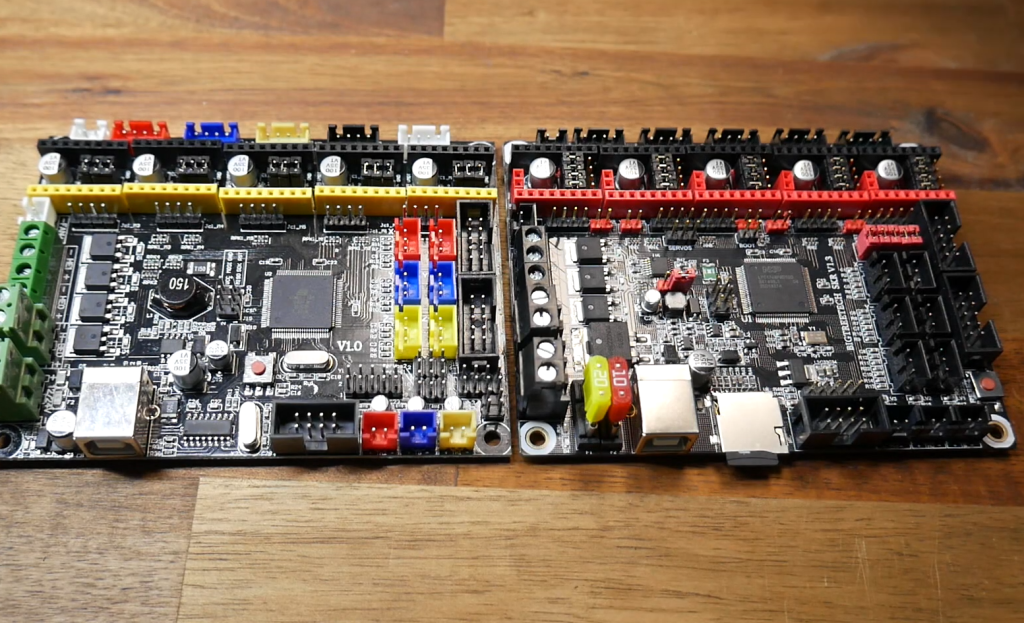

Additionally, you should also make sure that your driver is compatible with the type of motor controller or board you are using. For example, if you’re using a RepRap controller, then make sure that the driver you select is compatible with this type of board. This will help ensure that everything runs smoothly and without any problems.

What Is the Difference Between SPI (TMC5160) and UART (TMC2209)?

The TMC5160 and the TMC2209 are two popular motor control technologies used in 3D printing. Both offer a high level of control over stepper motors, but they have important differences that make them suitable for different applications.

The most significant difference between these two technologies is their communication protocol. The TMC5160 uses SPI (serial peripheral interface) to communicate with the electronics, while the TMC2209 uses UART (Universal Asynchronous Receiver/Transmitter).

UART is a simpler protocol for communication between devices. It is easy to set up and requires only two wires, plus power and ground connections. This makes it ideal for applications where space and complexity are limited. The downside of UART is that it has slower transmission speeds than SPI.

SPI, on the other hand, offers higher data transfer rates and more flexibility when communicating between devices. It requires more wires to be connected (four or five), but this can be beneficial in certain applications where faster communication between multiple stepper motors is necessary.

The TMC5160 is also capable of delivering higher levels of power, making it better suited for more powerful applications such as those involving large motors and/or heaters. This extra power also makes the TMC5160 more efficient in certain situations. Both technologies offer a wide range of features and can be used to create smooth motion control, but the specific application will determine which one is best suited. Ultimately, the choice of which motor control technology to use will depend on the specific needs of a project.

In addition to their communication protocols and power capabilities, they also differ in terms of their features. The TMC5160 has some additional features such as stallGuard2 for sensorless homing, spreadCycle for quieter operation at low speeds, and CoolStep for dynamic current regulation. The TMC2209, on the other hand, has features such as StallGuard and microPlyer for more precise torque control and quieter operation at low speeds.

Both technologies have their advantages and disadvantages, so it is important to take the time to consider your specific needs before deciding which one is right for you. As always, it is important to do your research and make sure you are making the right decision for your application. No matter which one you choose, both technologies provide reliable and efficient motor control for 3D printing applications.

FAQ

What is the difference between the 5160 and 2209 stepper drivers?

The 5160 stepper driver is a two-phase unipolar driver, while the 2209 is a four-phase bipolar driver. The 5160 is designed for lower current applications and can handle up to 2A per phase without additional heat sinks or cooling fans, while the 2209 can handle up to 4A per phase. Additionally, the 2209 has an adjustable current control feature that allows for greater precision and smoother motor performance.

What are the advantages of using a stepper driver?

Stepper drivers offer several advantages over other types of motor control systems, including accuracy, reliability, repeatability, low power consumption, and cost-effectiveness. Stepper drivers can also provide more precise position feedback than traditional servos or DC motors, which is especially useful for robotic and automation applications. In addition, stepper drivers are typically simple to install and configure. Finally, many stepper driver models are available with a variety of features that can be customized to meet specific needs.

What is the main difference between TMC2660 and TMC2209?

The TMC2660 is a high-performance stepper motor driver, while the TMC2209 is a more economical alternative. The main difference between them is that the TMC2660 has an extended range of current settings and quieter operation than its lower-cost counterpart. Additionally, the TMC2660 offers stallGuard2 and stealthChop2 technology for improved performance. In comparison, the TMC2209 does not offer these advanced features, but it is still suitable for many basic applications. Both drivers can be configured using Trinamic’s PC software or through a web interface.

What are the benefits of using an external stepper driver?

An external stepper driver offers several advantages over other motor control systems, including improved accuracy, reliability, repeatability, and cost-effectiveness. External stepper drivers can also provide more precise position feedback than traditional servos or DC motors, which is especially useful for robotic and automation applications. Additionally, external stepper drivers are typically simple to install and configure, making them ideal for a variety of applications. Finally, many external driver models are available with a variety of features that can be easily customized to meet specific needs.

What is the best type of stepper driver for my application?

The best type of stepper driver for your application will depend on several factors, such as the motor size, current requirements, available space, and cost. Generally, bipolar drivers are more suitable for low-current applications, while unipolar drivers are better suited for higher-current applications. Additionally, some stepper driver models offer advanced features such as adjustable current control or StallGuard2 that can improve performance in certain applications. Ultimately, it is best to consult with an experienced engineer to determine the best type of stepper driver for your application.

What safety considerations should I keep in mind when using a stepper driver?

When using a stepper driver, it is important to take safety precautions to ensure that the motor and other components are not damaged. Some safety considerations include proper heat dissipation, ensuring that all connections are secure, avoiding over-tightening of screws or nuts, and protecting against electrical shock. It is also important to use the appropriate power supply and adjust current settings according to your application’s requirements. Finally, it is best to consult with an experienced engineer if you have any questions or concerns about the safety of your setup.

What is the difference between TMC2100 and TMC2130 vs TMC2208?

The TMC2100 and TMC2130 are both high-performance stepper motor drivers, while the TMC2208 is a more economical alternative. The main difference between them is that the TMC2100 and 2130 offer a wider range of current settings, quieter operation, and advanced features such as stallGuard2 and stealthChop2 technology for improved performance. In comparison, the TMC2208 does not have these advanced features, but it is still suitable for many basic applications. Additionally, all three drivers can be configured using Trinamic’s PC software or through a web interface.

What are the different types of stepper motor drivers?

The two main types of stepper motor drivers are unipolar and bipolar drivers. Unipolar drivers are designed for lower current applications and can handle up to 2A per phase without additional heat sinks or cooling fans. Bipolar drivers, on the other hand, are more suitable for higher-current applications and can handle up to 4A per phase. Additionally, many stepper motor driver models offer adjustable current control features that allow for greater precision and smoother motor performance. Some hybrid drivers offer both unipolar and bipolar configurations, allowing for greater flexibility in motor control applications. Finally, many stepper driver models are available with a variety of features that can be customized to meet specific needs.

What is the difference between a micro stepping driver and a full-step driver?

A micro-stepping driver allows for a greater range of motion than a full-step driver by dividing each step into smaller increments. This type of driver is typically used in applications where precision and smoothness are important, such as robotic arms or 3D printing. In comparison, a full-step driver only moves in discrete steps, which can cause the motor to vibrate if

A micro-stepping driver is more precise than a full-step driver, as it divides each step into smaller increments. This type of driver is typically used in applications where precision and smoothness are important, such as robotic arms or 3D printing. Additionally, micro-stepping drivers can provide quieter operation and less torque ripple, which can improve motor performance overall. However, the smaller steps can require more current than full-step drivers, so it is important to adjust the motor current settings accordingly. Finally, most stepper driver models are capable of both micro-stepping and full-step operation, allowing for greater flexibility in motor control applications.

Conclusion Paragraph

So, TMC2209 and TMC5160 stepper drivers are both excellent options for improving your 3D printer performance. Although the TMC2209 is a great stepper driver with its small form factor, high power efficiency, and advanced features, it might not be enough to match the level of precision that the TMC5160 offers. The TMC5160 has an integrated encoder feedback system which helps to ensure high accuracy, making it ideal for 3D printing applications that require extreme precision. Additionally, its robust design allows it to handle larger motors and higher currents than the TMC2209.

Both stepper drivers can be used to improve the performance of your 3D printer, but depending on your specific needs you will need to decide which one is best suited for you. If you are looking for a reliable stepper driver that can handle large currents and offer higher precision, then the TMC5160 is the ideal choice. However, if your requirements are more modest and you don’t need extreme levels of accuracy, then the TMC2209 may be a better option.

Useful Video: TMC2209 and TMC 5160: Guide for MKS Gen L and SKR V1.3

References:

- https://www.elprocus.com/what-is-a-stepper-motor-driver-types-and-its-applications/

- https://www.utmel.com/components/tmc5160-vs-tmc2209-how-to-differentiate?id=1900