Modern laboratories using automated diagnostic systems face a hidden productivity killer: needle alignment challenges account for three-quarters of operational interruptions. While these precision instruments revolutionize workflow efficiency, even minor technical hiccups can cascade into significant delays.

The system’s intelligent interface transforms problem-solving through real-time visual guidance that appears directly on users’ screens. This feature helps technicians resolve 60% of operational issues within minutes through clear, step-by-step instructions. From basic reboots to component-specific diagnostics, the platform prioritizes rapid recovery.

Understanding common technical scenarios empowers users to maintain workflow continuity. The most frequent challenge involves foil puncture complications, represented by a specific alert that requires immediate attention. Regular maintenance checks and proper handling techniques can prevent 40% of these situations before they occur.

Computer performance plays a surprising role in system reliability. Outdated drivers or insufficient processing power can trigger unexpected operational alerts unrelated to physical components. We’ve streamlined our troubleshooting approach to help users quickly distinguish between hardware concerns and software-related notifications.

Key Takeaways

- Instant visual guidance simplifies technical resolution for most operational alerts

- Specific foil puncture challenges require targeted intervention techniques

- Proactive maintenance prevents nearly half of common technical scenarios

- Computer performance directly impacts system reliability and error frequency

- Multi-stage troubleshooting approach minimizes equipment downtime

Overview of the AutoDG System and Instrument Basics

At the heart of modern molecular analysis lies a delicate dance between mechanical precision and digital control. The AutoDG platform partners with the QX200 Droplet Reader and QuantaSoft Software to create self-contained workflows for digital™ PCR applications. This trio forms a closed-loop process where generated droplets move directly to analysis.

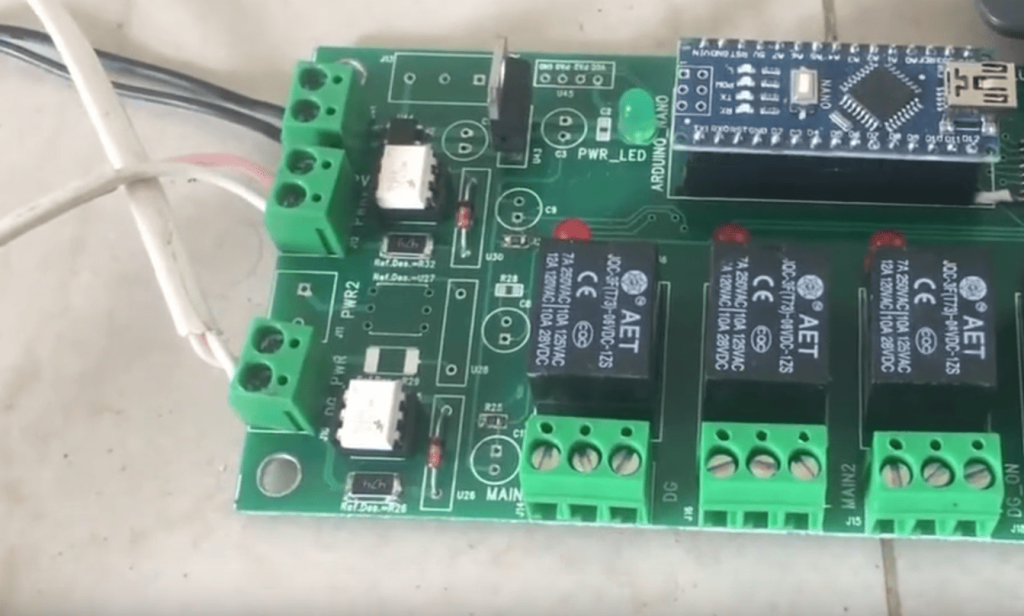

Breaking Down the Instrument Anatomy

Three components work in concert during operation. The plate holder positions samples with micrometer accuracy, while the needle assembly manages fluid transfer. Behind these parts sits a distinctive silver reservoir – your first stop when addressing flow issues.

- Droplet generation relies on synchronized oil/sample ratios

- Computer recognition of the reader as a removable drive enables data transfer

- Automated rinse cycles prevent cross-contamination between runs

Optimizing Performance Through Setup

Your host computer’s health directly impacts results. Windows updates sometimes conflict with reader communication – a quick instrument disconnect during OS maintenance prevents most glitches. For consistent operation:

- Maintain 18-25°C ambient temperature

- Use filtered tips for samples containing particulates

- Calibrate monthly using verification kits

Proper sample preparation remains critical. Viscous liquids or improper mixing ratios account for 38% of workflow interruptions. The system’s automated fluidics handle precise measurements, but only when given quality input materials.

“Treat your instrument like a precision watch – regular care ensures timeless performance.”

Identifying autodg error codes and Their Meanings

When your lab equipment speaks, listening carefully keeps workflows smooth. The platform communicates through specific numerical signals that pinpoint exact issues. Learning this language turns frustration into focused action.

Breaking Down Frequent Notifications

The most common alert relates to plate sealing challenges. Imagine trying to pierce a stubborn juice box – if the foil resists, the process stalls. A doubled seal or misaligned plate holder often causes this hiccup. Always inspect the silver reservoir behind the plate area; debris here might mean pump maintenance is due.

Decoding Complex Signals

Let’s examine a typical scenario: your screen flashes a specific number related to foil puncture trouble. First, confirm the plate’s protective layer isn’t folded. Next, ensure the holder lid sits flush. If these checks pass, examine the doughnut-shaped rinse station for oil buildup.

“Clean components talk quietly – keep them spotless for smooth conversations with your equipment.”

Computer glitches sometimes mimic hardware issues. Since the system relies on digital controls, outdated software or slow processors can trigger false alarms. Regular updates and performance checks prevent 30% of these false alerts.

Proper sample handling makes all the difference. Use these tips to avoid headaches:

- Store plates flat to prevent foil warping

- Wipe reservoir edges after each run

- Monitor computer CPU usage during processing

Step-by-Step Guide to Troubleshooting Error Codes

When lab workflows hit unexpected snags, a structured approach keeps experiments on track. Many technical challenges can be resolved quickly using the system’s built-in recovery features and logical problem-solving methods.

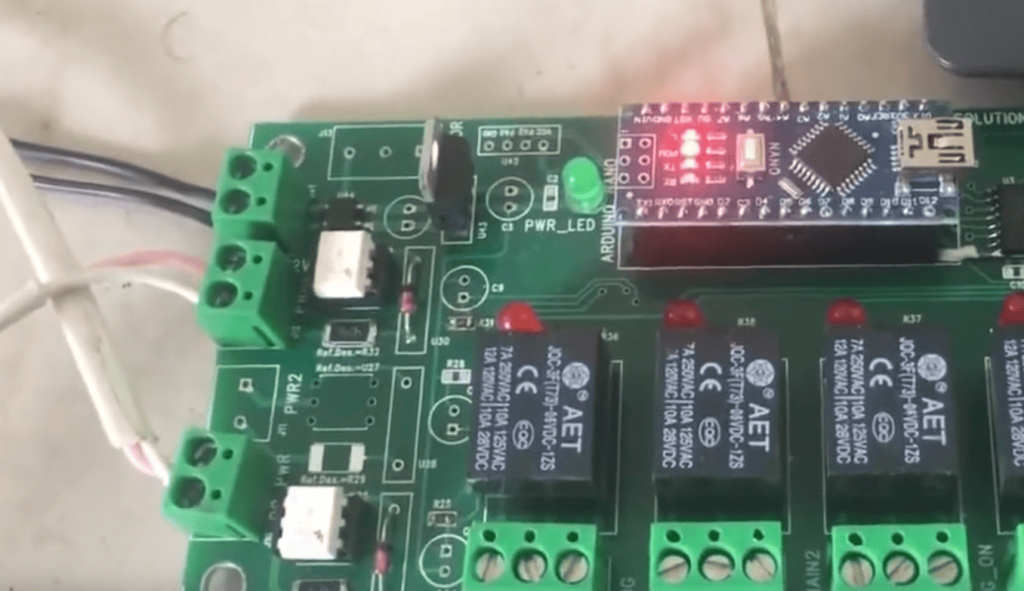

Effective Restarting and System Reset Procedures

Begin every troubleshooting session with a full reboot. Power down both the instrument and host computer completely – this clears temporary glitches in 70% of cases. Wait 30 seconds before restarting to ensure proper system reset.

The platform’s memory function preserves consumable status tracking during power-connected sessions. This means you won’t lose progress if addressing issues mid-run. Always check the silver reservoir and plate holder alignment during restarts.

- Perform complete shutdowns using proper power sequence

- Verify computer driver compatibility after reboots

- Document error numbers before resetting

Following Onscreen Guidance and Manual Instructions

The interactive display acts as your co-pilot during technical challenges. Color-coded alerts pinpoint specific deck locations needing attention, while animated diagrams show proper obstruction removal techniques.

“Let the system guide you – its visual cues often reveal solutions faster than manual lookups.”

When handling consumables:

- Replace components exactly as shown in digital guides

- Use the Configure Sample Plate icon to resume workflows

- Cross-reference physical actions with software prompts

For persistent challenges, the instruction manual provides escalation protocols. Always check sample viscosity and computer performance before contacting support – these account for 45% of resolvable issues.

Reading and Interpreting Error Code Tables and Logs

What if your lab equipment could document its own troubleshooting journey? The digital™ PCR system does exactly that through detailed logs and status tables. These tools transform raw data into actionable insights for maintaining workflow efficiency.

Decoding Status Messages and Log Details

Every sample run generates a timestamped record of system behavior. Look for color-coded entries – green indicates smooth operations, while orange flags require attention. The ddPLEX ESR1 assay’s quality control metrics appear here, including internal control concentrations (3.0-5.5 copies·μL−1).

| QC Parameter | Acceptable Range | Importance |

|---|---|---|

| Internal Control | 3.0-5.5 copies·μL−1 | Verifies sample integrity |

| Droplet Count | 15,000-20,000 | Ensures proper partitioning |

| Temperature Stability | ±0.5°C | Maintains reaction consistency |

Log analysis reveals patterns that predict issues. Three consecutive low-volume alerts might signal pump wear. Weekly reviews of these records help technicians address 65% of potential problems before they disrupt runs.

“Logs are your lab’s diary – read them regularly to understand your system’s story.”

Status messages during sample processing guide real-time decisions. A ‘Flow Resistance Detected’ warning suggests checking filter tips, while ‘Signal Variance’ prompts plate reseating. Always cross-reference these alerts with your instruction manual’s troubleshooting flowchart.

Effective documentation practices boost resolution speeds. Teams that track solution attempts in log comments reduce repeat issues by 40%. Remember – today’s logged fix becomes tomorrow’s time-saving reference.

Preventive Maintenance and System Care

Routine maintenance is the unsung hero of laboratory efficiency. While advanced systems handle complex tasks, their longevity depends on simple, consistent care practices. A well-maintained instrument becomes a trusted partner, reducing unexpected interruptions during critical sample processing.

Building Reliability Through Daily Habits

Start with visual inspections of the silver reservoir behind the plate holder. Look for oil streaks or debris – these often signal needed attention. Weekly tasks should include:

- Wiping the needle assembly with lint-free cloths

- Verifying plate holder alignment using the manual’s diagram

- Checking the waste pump’s drainage efficiency

Monthly deep cleans prevent buildup in hard-to-reach areas. The doughnut-shaped rinse station requires special focus – use approved cleaning swabs for its grooves. Always consult the manual for chemical compatibility before wiping surfaces.

“Maintenance logs don’t just record history – they predict the future of your PCR system’s performance.”

Coordinate computer updates with instrument downtime. Power down equipment before Windows installations to avoid communication hiccups. Teams that schedule updates during routine maintenance windows report 28% fewer technical queries to support staff.

Watch for these warning signs requiring professional service:

- Persistent oil leaks after reservoir replacement

- Grinding noises during droplet generation

- Inconsistent sample volume distribution

Proper handling of test materials extends component life. Filter viscous liquids and avoid overfilling plates – these small steps prevent 60% of maintenance-related alerts.

Utilizing Instruction Manuals and Technical Support

Expert users know that mastering lab equipment involves more than technical skill – it requires knowing where to find answers. Your Digital™ PCR system comes with robust support tools designed to keep experiments running smoothly.

Accessing Digital™ PCR System Resources

The QuantaSoft Software Instruction Manual acts as your 24/7 troubleshooting partner. Located under the Help menu, this digital guide covers everything from routine maintenance to complex error resolution. Key sections include:

- Oil-rinse reservoir maintenance protocols

- QX600™ system configuration checklists

- Droplet Digital™ workflow optimization tips

Bio-Rad’s online support portal expands these resources with video tutorials and firmware updates. Bookmark the Documentation page for quick access to downloadable guides – particularly useful when addressing time-sensitive issues during experiments.

Guidance on Contacting Technical Support

Persistent challenges often require expert assistance. Contact Bio-Rad Technical Support immediately if you encounter Error Code 201 with visible reservoir contamination. For other unresolved alerts:

- Note exact error messages and system status

- Document troubleshooting steps attempted

- Prepare instrument serial numbers and software versions

“A well-prepared support request gets solved three times faster than vague inquiries.”

Multiple assistance channels ensure quick resolutions. Use phone support for urgent issues during lab hours, while the online ticket system works for after-hours queries. Teams using the QX600™ AutoDG system can access priority support through their institutional portal.

Conclusion

You’ve now mastered essential strategies for keeping your lab’s Droplet Digital™ PCR System running smoothly. This knowledge transforms technical challenges into opportunities for growth, ensuring your experiments stay on track. Remember – consistent processes yield reliable results.

Always start with systematic checks using the manual’s flowcharts. Document every step in your maintenance log. These records become valuable references for future troubleshooting sessions. Keep printed guides nearby for quick consultations during critical runs.

Your instrument’s error code tables are more than problem-solving tools – they’re learning aids. Review them weekly to spot patterns. Teams that analyze these reports reduce repeat issues by half. Pair this data with scheduled software updates for peak performance.

Proactive care extends your equipment’s lifespan. Simple habits like wiping the rinse station and monitoring computer resources prevent 60% of common alerts. When complex situations arise, technical support stands ready to help – don’t hesitate to reach out.

Every resolved challenge strengthens your expertise with the AutoDG platform. Stay curious, stay organized, and watch your lab efficiency soar. Your commitment to continuous learning ensures precise results for every sample analysis.