Arduino, renowned as a staple tool among hobbyists and educators, has also surprisingly carved a niche for itself in the industrial sector. This open-source electronics platform, characterized by its easy-to-use hardware and software, empowers industries to develop, prototype, and manufacture complex automation systems. Its versatility and adaptability are what make Arduino an asset in the industrial landscape.

What is Arduino?

How Does Arduino Work?

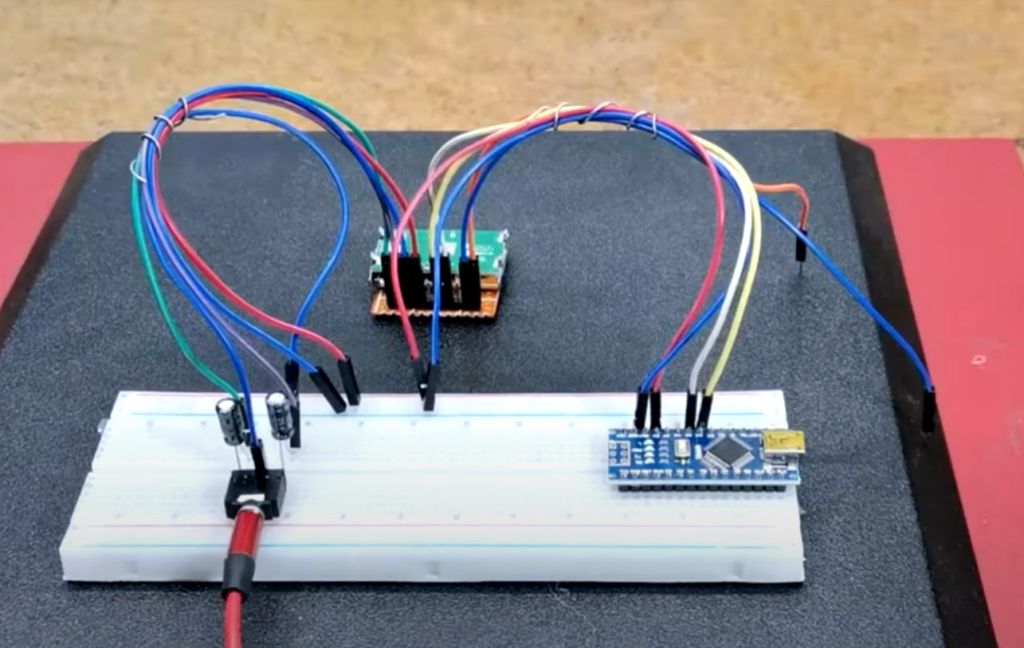

Arduino works by interpreting and executing code written in the Arduino programming language, which is based on a simplified version of C++. The code tells the microcontroller what to do, such as read inputs from sensors or control outputs to motors. The microcontroller then executes these instructions, allowing users to create a wide range of projects and applications.

History of Arduino

As mentioned, Arduino was first developed in 2005 by a group of students at the Interaction Design Institute Ivrea in Italy. The initial goal was to create an easy-to-use tool for students and non-experts to quickly learn and prototype interactive projects. The project gained popularity and eventually evolved into the open-source platform it is today.

Advantages of Using Arduino in Industry

Arduino is a popular open-source electronic prototyping platform that has gained immense popularity among engineers, makers and hobbyists. However, the use of Arduino is not limited to just these groups of people; it has also found its way into various industries. In this section, we will discuss the advantages of using Arduino in industry. [1]

Cost-effective and Flexible

One of the main reasons why Arduino is widely adopted in industry is its cost-effectiveness. Traditional industrial control systems can be expensive, making it difficult for smaller businesses to implement automation solutions. In comparison, Arduino boards are affordable and offer a wide range of capabilities, making it an attractive option for industries looking to automate their processes. Additionally, Arduino’s modular design allows for easy integration with existing industrial systems, making it a flexible and customizable solution.

User-friendly

Another advantage of using Arduino in industry is its user-friendly nature. The platform’s simple programming language, coupled with its extensive community support, makes it easy for even non-technical individuals to learn and use. This ease of use means that industries can quickly train their employees to work with Arduino-based systems without the need for specialized knowledge or skills. This, in turn, can lead to increased productivity and efficiency within the workplace.

Versatility

Arduino’s versatility is another factor that makes it well-suited for industrial use. The platform supports a wide range of sensors, actuators, and communication protocols, making it suitable for various applications. From simple data logging to complex process control systems, Arduino can handle a diverse range of tasks. Additionally, its compatibility with other software tools such as MATLAB and Simulink allows for more advanced control and analysis capabilities in industrial settings.

Rapid Prototyping and Development

In industries, time is of the essence, and any delays in product development can result in significant financial losses. Arduino’s rapid prototyping capabilities come in handy here as it allows for quick proof of concept testing and iteration before moving on to production. This feature not only speeds up the development process but also minimizes risks by catching potential issues early on. Moreover, Arduino’s open-source nature means that industries can easily access and modify existing designs to fit their specific needs, further reducing development time.

Scalability

Lastly, Arduino’s scalability is another advantage that makes it a viable option for industrial use. With the introduction of boards like the Arduino Mega and Due, which offer more memory and processing power, the platform can now handle larger-scale projects and accommodate growing businesses’ needs. Additionally, industries have the option of creating custom PCBs based on the Arduino design for even greater scalability and control over their systems. [2]

Hardware and Software Considerations

While Arduino offers numerous advantages in industrial settings, there are a few factors that industries must consider before adopting it. Firstly, they should carefully evaluate their project requirements and determine if Arduino’s capabilities align with their needs. Moreover, industries should also consider the reliability and ruggedness of the hardware used, as industrial environments can be harsh. They may need to opt for more robust components or enclosures to ensure the longevity of their systems. Lastly, it is crucial to have proper maintenance procedures and backups in place to prevent downtime in case of failures.

Applications of Arduino in Industry

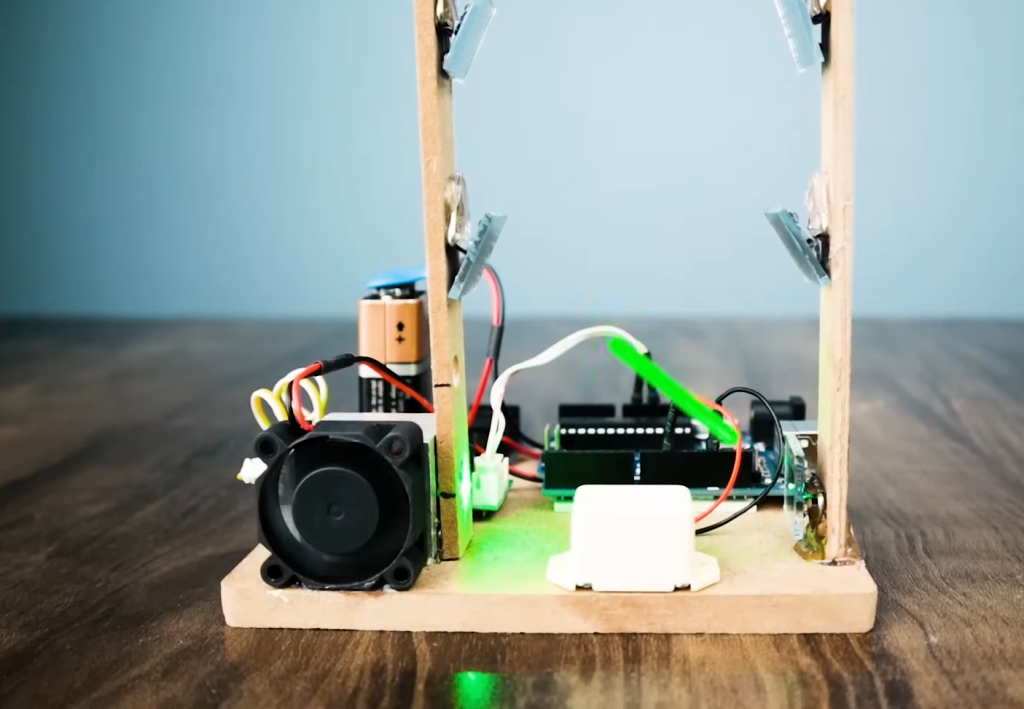

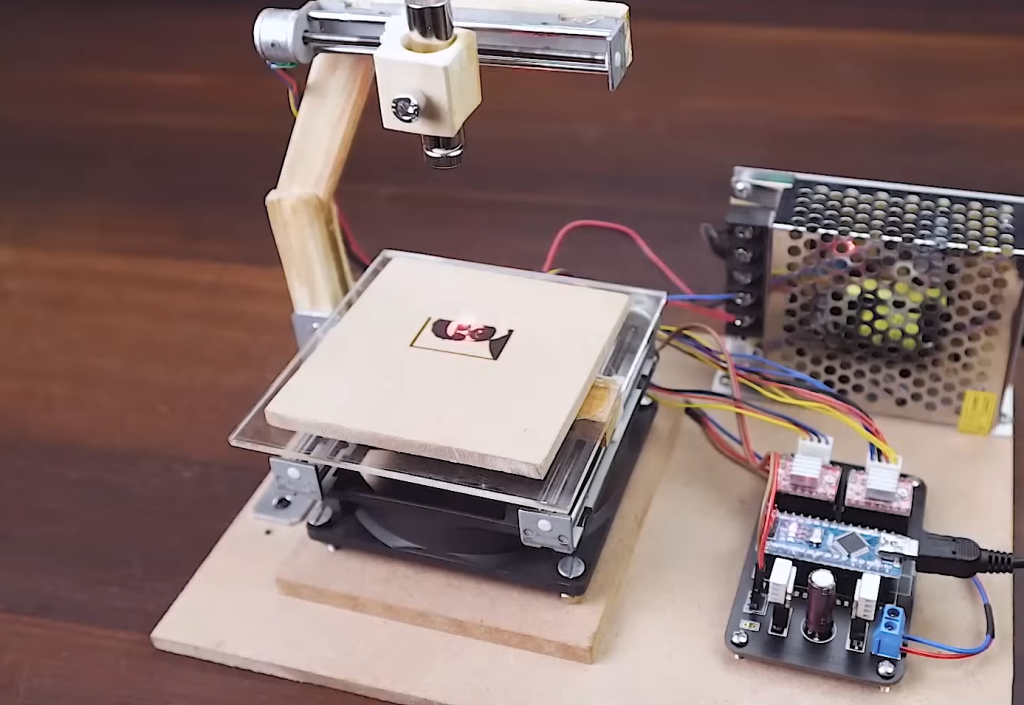

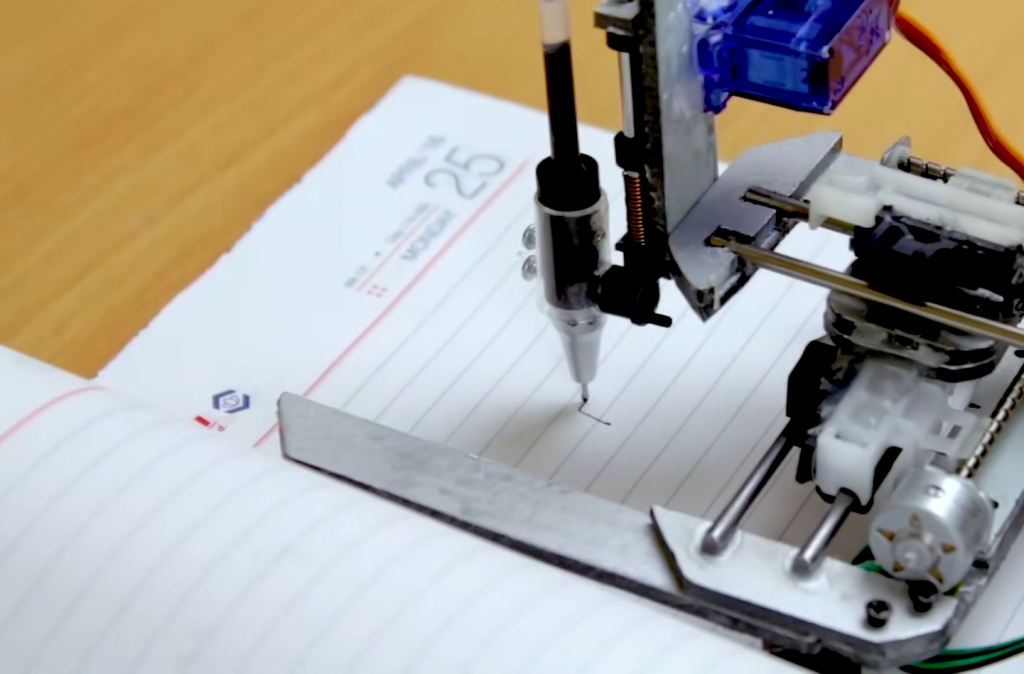

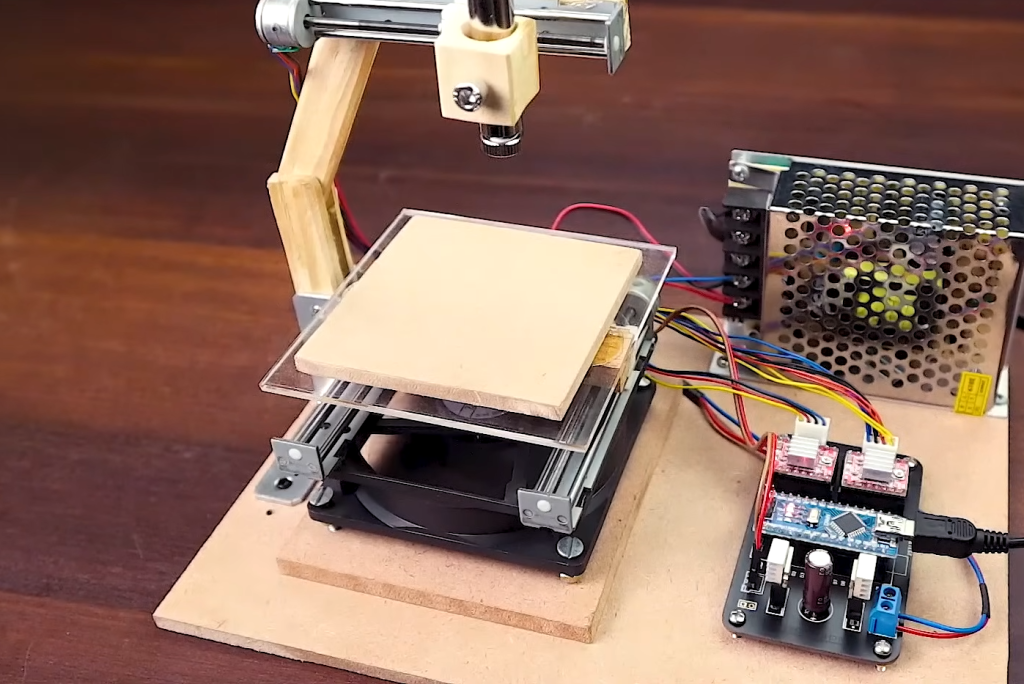

Arduino’s versatility and low cost have made it a popular choice for various applications in industry. Some common uses include process control, data logging, monitoring and alarm systems, robotics, and automation. Additionally, Arduino has also found its way into the Internet of Things (IoT) space, where it is used to collect and transmit sensor data from industrial equipment to the cloud for analysis and optimization. Overall, Arduino’s wide range of capabilities makes it a valuable tool for industries looking to innovate and streamline their processes.

Challenges and Solutions for Using Arduino in Industry

When it comes to using Arduino in industry, there are some unique challenges that need to be addressed. However, with the right solutions and strategies in place, these challenges can easily be overcome. In this section, we will discuss some of the common challenges faced by industries when implementing Arduino technology and explore potential solutions for them.

Challenge 1: Lack of Technical Expertise

One of the main challenges industries face when adopting Arduino technology is a lack of technical expertise. Many companies do not have employees with prior experience in using Arduino, which can lead to difficulties in implementing and maintaining the technology. Furthermore, due to the constantly evolving nature of Arduino, it can be challenging for companies to keep up with the latest updates and advancements.

Solution:

To address this challenge, industries can invest in training and upskilling their employees. This can include organizing workshops or enrolling employees in online courses related to Arduino. Additionally, hiring experienced professionals who have prior knowledge of working with Arduino can also help bridge the gap in technical expertise. Companies can also stay updated on the latest advancements in Arduino by regularly attending conferences and networking with experts in the field. [3]

Challenge 2: Scalability

Arduino is often associated with hobbyist projects and prototyping, which may lead industries to question its scalability for large-scale production. Industries need to ensure that Arduino technology can handle larger workloads and is reliable enough for industrial use.

Solution:

To address this challenge, industries can opt for more advanced versions of Arduino boards, such as the Arduino Mega or Due, which are designed for larger and more complex projects. Additionally, companies can also collaborate with suppliers who offer custom-made solutions to meet their specific production needs. This can involve modifying the hardware or firmware of Arduino boards to make them more suitable for industrial use.

Challenge 3: Integration with Existing Systems

Another challenge faced by industries is integrating Arduino technology with their existing systems. Since Arduino uses its own programming language, it may not be compatible with the software and applications used by an industry. This can lead to difficulties in data exchange and communication between different components of a production process.

Solution:

To address this challenge, industries can use Arduino shields, which are add-on boards that provide additional functionalities to the base Arduino board. These shields can help bridge the gap between different systems by providing compatibility with various communication protocols and interfaces. Additionally, companies can also develop custom software or firmware that can be integrated with their existing systems, allowing for seamless data exchange.

Future of Arduino in Industry

Despite these challenges, the use of Arduino technology in industry is expected to continue growing in the coming years. With its low cost, flexibility, and ease of use, Arduino offers a range of applications for industrial processes. In fact, many industries are already using it for tasks such as data logging, automation, and quality control. As more companies invest in training their employees and customizing solutions to fit their specific needs, we can expect to see even more innovative uses of Arduino in industry in the future. Additionally, with the constant advancements and updates being made to Arduino technology, it will continue to play a significant role in driving industrial efficiency and productivity.

Overall, the future looks bright for Arduino in industry as companies embrace its potential and reap the benefits it has to offer. With the right strategies and solutions in place, industries can overcome any challenges they face and successfully incorporate Arduino into their production processes. As a result, we can expect to see increased efficiency, cost-effectiveness, and innovation within various industrial sectors thanks to the use of Arduino technology. [4]

Limitations of Arduino in Industry

While Arduino does offer a range of benefits for industry use, it also has its limitations. Some industries may have specific requirements that cannot be met by using Arduino technology alone. Additionally, the open-source nature of Arduino may also pose security concerns for certain industries.

Is Arduino Used In Real Life Products?

Despite its limitations, Arduino is being used in various real-life products and applications. From consumer electronics to industrial automation systems, Arduino has found its way into a wide range of products. Some notable examples include 3D printers, home automation systems, robotics projects, and even wearable technology. Additionally, companies such as Bosch and Philips have incorporated Arduino into their products for added functionality and ease of use. As the adoption of Arduino continues to increase, we can expect to see it being used in even more real-life applications in the future.

Can Arduino Be Used Commercially?

Yes, Arduino can be used commercially in a variety of industries. As mentioned earlier, many companies are already using Arduino for tasks such as data logging and automation. Additionally, the availability of shields and custom solutions makes it possible to use Arduino in commercial applications that require specific functionalities. However, it is important to note that certain industries may have stricter regulations and standards that need to be met before implementing any technology, including Arduino. It is always advisable to thoroughly research and consult relevant experts before incorporating Arduino into any commercial project.

Is It Legal To Sell Arduino Projects?

Arduino is a popular open-source hardware and software platform that has revolutionized the world of electronics and programming. The versatile nature of Arduino makes it suitable for a wide range of projects, from simple DIY home automation to complex industrial applications. With its ease of use and low cost, many people are now wondering if they can turn their passion for Arduino into a profitable business by selling their projects. However, before diving into the world of commercializing Arduino projects, it is important to understand the legal implications involved.

Understanding Arduino’s Licensing

Exceptions for Commercial Use

There are two main exceptions that allow for commercial use of Arduino projects:

- Original Creations: If you have created something entirely new using the Arduino platform, you are free to sell it commercially. This means that if your project is not directly based on any existing open-source design or code, you can profit from selling it. However, it is always a good practice to give credit to the Arduino community and acknowledge their contributions.

- Modifications: If you have made significant modifications to an existing open-source Arduino project, you can sell your modified version as long as you comply with the CC-BY-SA license. This means that you must share your modifications under the same license and give credit to the original creators.

Potential Risks

While there are exceptions for selling Arduino projects, it is important to note that there are still potential risks involved. The main concern is the possibility of copyright infringement. If your project closely resembles an existing commercial product or uses proprietary code without permission, you may face legal action from the original creators. It is always best to do thorough research and ensure that your project does not infringe on any copyrights.

Why Is Arduino So Expensive?

One of the main appeals of Arduino is its low cost compared to other microcontroller platforms. However, some may argue that Arduino boards and components are still relatively expensive, especially for those on a tight budget. So why is this the case?

High Quality Components

One of the reasons for Arduino’s cost is the use of high-quality components. The creators of Arduino place a strong emphasis on quality and reliability, which means using more expensive components that are less likely to fail. This ensures that users have a good experience with their projects and can trust in the performance and durability of Arduino.

Support and Development

Arduino is not just a product, but a community-driven project. The cost of Arduino boards also includes support for the development of new products and software updates. This means that with each purchase, users are not only getting a physical board but also contributing to the growth and improvement of the platform as a whole.

Supply and Demand

Lastly, the cost of Arduino also factors in supply and demand. As the popularity of Arduino increases, so does the demand for its products. This allows for economies of scale, which can bring down production costs. However, at the same time, high demand may also result in higher prices due to limited supply. [6]

FAQs

What is Arduino used for in the industry?

Arduino is used in various industries for a wide range of applications such as automation, data logging, prototyping, and more. Its versatility makes it suitable for both small-scale and large-scale industrial projects. Some examples of industries where Arduino is used include manufacturing, agriculture, healthcare, and transportation.

Can I sell my Arduino projects commercially?

Yes, there are exceptions that allow for commercial use of Arduino projects. However, it is important to understand the licensing requirements and potential risks involved before selling your projects commercially. It is also a good practice to give credit to the original creators and acknowledge their contributions.

Why is Arduino more expensive than other microcontroller platforms?

Arduino’s cost includes high-quality components, support for development and updates, as well as supply and demand factors. Despite its relatively low cost compared to other platforms, these aspects contribute to the overall price of Arduino products.

In what industries is Arduino commonly used?

Arduino can be found in various industries, including manufacturing, agriculture, healthcare, transportation, and more. Its versatility allows for a wide range of applications in both small-scale and large-scale projects.

Why is Arduino preferred in industrial applications?

Arduino’s ease of use, affordability, and versatility make it a popular choice for industrial applications. Its open-source platform also allows for easily customizable solutions to fit specific industry needs. Additionally, Arduino has a large community of users and developers who constantly contribute to its development and support.

What are the benefits of using Arduino in industrial settings?

Some of the benefits of using Arduino in industrial settings include cost-effectiveness, ease of use, flexibility, and availability of a large community for support. Additionally, with its open-source nature and customizable solutions, Arduino can cater to specific industry needs and requirements.

What are some examples of industrial projects using Arduino?

Some examples of industrial projects using Arduino include automated assembly lines, environmental monitoring systems, precision farming equipment, and medical devices. These are just a few of the many possible applications of Arduino in various industries. Overall, Arduino’s versatility allows for endless possibilities in industrial settings.

Are there limitations to using Arduino in an industrial context?

While Arduino has many benefits in industrial applications, there are also limitations to consider. These may include limited processing power compared to other microcontrollers and the need for additional components or shields for certain projects. It is important to thoroughly research and understand the capabilities and limitations of Arduino before using it in an industrial context. Overall, Arduino can be a great tool for industrial projects but may not always be suitable for every application. Additionally, it is essential to ensure compliance with any industry regulations or standards when using Arduino in these settings.

Conclusion

While it is evident that Arduino has found its use in numerous industries, it is also clear that its impact and influence are growing rapidly. The open-source platform caters to the needs of both hobbyists and professionals, making it a versatile tool. Additionally, Arduino’s ease of use and low cost have made it accessible even to individuals with little or no technical background. This has contributed to its widespread adoption in various industries such as manufacturing, agriculture, healthcare, and more.

Furthermore, Arduino’s compatibility with other hardware and software tools makes it a valuable asset for businesses looking to integrate different systems or devices. Its flexibility allows for customization and adaptation to specific industry needs, making it a popular choice among professionals. With its constant evolution and the continuous development of new boards, shields, and libraries, Arduino is expected to see even more widespread use in industries in the future.

In conclusion, Arduino has proven to be a valuable asset in various industries, thanks to its versatility, accessibility, and compatibility. Get your hands on an Arduino board today and join the growing community of makers, engineers, and professionals utilizing this powerful tool in their work. Start exploring the world of Arduino today!

Useful Video: PLC vs Arduino (Can Arduino be used in Industries?, Don’t MAKE a mistake)

References:

- https://control.com/technical-articles/arduino-applications-in-industrial-automation/

- https://forum.arduino.cc/t/is-arduino-suitable-for-industrial-use/357386

- https://www.industrialshields.com/blog/arduino-industrial-1/is-arduino-suitable-for-industry-475

- https://roboticsbackend.com/is-arduino-used-in-real-life-products/

- https://www.arrow.com/en/research-and-events/articles/arduino-uno-r3-industrial-solutions

- https://www.electronicsweekly.com/news/products/bus-systems-sbcs/arduino-takes-final-step-to-industrial-automation-2023-02/