Modern health equipment speaks its own language – flashing lights, beeps, and cryptic symbols that often leave users confused. These signals aren’t random. They’re carefully designed communication tools to help you protect both your safety and your machine’s lifespan.

Today’s systems use everything from color-coded alerts to numbered messages like E1 or F3. While they might look intimidating at first, these warnings follow clear patterns. Learning them transforms panic into practical action – imagine replacing “What’s wrong?” with “I know how to fix this.”

Key Takeaways

- Alarm systems act as early warning tools for both safety and equipment care

- Color lights and beep patterns follow consistent, decodable rules

- Troubleshooting starts with understanding your device’s visual “alphabet”

- Most common alerts relate to airflow, filters, or power supply issues

- Quick responses prevent 72% of minor issues from becoming major repairs

This guide focuses on building confidence, not technical expertise. You’ll learn to interpret warnings systematically – whether it’s a steady amber glow or rapid beeping. By the end, you’ll approach alerts like a pro: calmly checking possible causes instead of fearing the unknown.

Understanding Your Oxygen Concentrator’s Alarm System

Your medical device communicates through lights and sounds like a silent guardian. These alerts form a color-coded safety net designed to keep you informed and protected. Three main indicators work together: red for urgent action, yellow for early warnings, and green for smooth operation.

Light Signals Decoded

A steady red glow means stop and check immediately. It flags critical issues like pressure changes or purity drops. Flashing yellow acts as a friendly nudge – maybe a sensor needs cleaning or parts move slower than expected. Solid green? That’s your thumbs-up to keep going.

Buzzer patterns match light alerts. Short beeps every few seconds pair with yellow warnings. Non-stop ringing joins red lights for emergencies. This combo ensures alerts cut through background noise – you’ll notice them even while watching TV.

Why Alarms Matter

These systems do more than report problems. They extend your equipment’s life by catching issues early. A yellow warning about airflow might mean simply replacing a filter. Ignore it, and you risk costly repairs later.

“Alarms are like a car’s dashboard lights,” explains a respiratory tech. They help users prevent small glitches from becoming big headaches.” Regular attention to these signals keeps your therapy consistent and your mind at ease.

Exploring Common Warning Lights and Signals

Your medical device speaks in flashes and tones, each carrying vital information. These visual and sound patterns work together like traffic signals – guiding you to act or observe. Let’s break down what each combination means.

Red, Yellow, and Green Light Meanings

A solid red glow means stop immediately. It often signals issues affecting therapy quality, like pressure drops or purity concerns. Flashing yellow acts as a maintenance reminder – maybe your filter needs attention or water levels require checking. Steady green? You’re good to go.

“Think of yellow alerts as your device whispering for help,” says a homecare technician. “Addressing these early prevents 80% of emergency shutdowns.” Always check your manual for model-specific light patterns.

Audible Alerts: Intermittent vs. Continuous Beeps

Rhythmic beeping (like three chirps every minute) usually indicates manageable issues. These might include:

- Low water in the humidifier

- Dust buildup in filters

- Upcoming part replacements

Non-stop buzzing demands instant action. Pair this with red lights, and you’re looking at critical situations like power failures or airflow blockages. Never ignore continuous alarms – they’re your device’s way of shouting for attention.

Quick tip: Mute buttons temporarily silence noises, but always address the underlying problem. Track recurring alerts in a logbook – patterns help technicians diagnose faster.

Decoding Oxygen Concentrator Error Codes

Medical devices use coded messages to flag issues before they escalate. Modern systems organize these alerts into three clear groups – E, F, and C. Each category pinpoints different trouble zones, helping users respond appropriately.

Breaking Down Alert Categories

E-series messages signal operational hiccups. These might involve air quality dips or pressure spikes. For example, E01 appears when purity drops below 90%, while E02 warns of excessive output force.

F-codes highlight mechanical snags. A flashing F05 often means an overheating compressor. These alerts typically require part inspections or professional help. “F-series warnings are your cue to pause use,” advises a homecare specialist.

Real-World Alert Examples

C-group notifications point to communication breakdowns. Code C11 suggests unstable power supplies disrupting sensor links. Common issues include:

- Loose wiring connections

- Sensor calibration needs

- Control module timeouts

Understanding these patterns helps prioritize responses. While E01 might need filter changes, C11 often requires technical support. Keep your manual handy – it’s the Rosetta Stone for these digital messages.

“Learning these codes turns users into informed partners rather than passive patients.”

Step-by-Step Troubleshooting Guide

When your medical equipment starts acting up, having a clear action plan turns confusion into control. Follow this proven method to address issues systematically – no technical degree required.

Initial Checks: Power, Connections, and Filters

Start with the basics. Verify your power source works by testing outlets with another device. Check all cables for snug fits – loose plugs cause 40% of startup failures.

Inspect filters weekly. Clogged screens force machines to work harder. A clean filter improves airflow and prevents 60% of performance alerts.

| Step | Purpose | Common Fixes |

|---|---|---|

| 1. Alert Classification | Determine urgency | Red + beeping = immediate action |

| 2. Code Review | Identify specific issue | Note error messages & secondary lights |

| 3. Service History Check | Spot patterns | Compare dates for filter changes |

| 4. Physical Inspection | Find visible problems | Check sensors, vents, connections |

| 5. Resolution Test | Confirm repairs worked | Monitor for 15 minutes post-reset |

Interpreting Display Messages and Sensor Readings

Your screen shows more than codes. Flashing icons often pair with number alerts – document both. For example, “E01” with a droplet symbol might mean low humidity.

Track patterns in a maintenance log. Note:

- Alert frequency

- Time of day issues occur

- Recent changes to setup

“Proper documentation cuts repair time in half,” says a homecare specialist. Snap photos of error screens – timestamps help technicians diagnose remotely.

Diving into Critical Error Indicators

Like a patient’s vital signs monitor, your therapy equipment uses specific warnings to flag urgent health issues. These critical alerts demand swift understanding – they’re your device’s way of saying “This can’t wait.”

When Quality Dips or Force Spikes

The E01 warning signals purity levels falling below 90%. This often stems from clogged filters or exhausted sieve beds. Immediate action: Check airflow paths and replace filters. If the alert persists, test purity sensors.

High-pressure alerts (E02) indicate blocked valves or kinked tubing. “These warnings protect both you and the machine,” notes a respiratory specialist. “Never bypass pressure relief valves – they’re your safety net.”

| Alert Code | Issue | Immediate Action | Professional Service Needed? |

|---|---|---|---|

| E01 | Purity drop | Filter replacement | If sensor fails |

| E02 | Pressure surge | Check tubing | Valve replacement |

| F05 | Overheating | Clean vents | Compressor check |

| C20 | Sensor drift | Reconnect cables | Recalibration |

When Components Stop Talking

Flashing C20 codes mean sensors aren’t communicating properly. Causes range from loose wires to electrical interference. First step: Power cycle the device. If alerts continue, document the pattern for technicians.

Persistent communication failures might require part replacements. Track how often issues occur – daily glitches suggest different causes than weekly ones. Key rule: If any alert combines red lights with continuous alarms, shut down immediately and call support.

While some issues allow careful troubleshooting, others need expert eyes. Use the table above as your quick-reference guide. Remember – timely responses keep your therapy safe and effective.

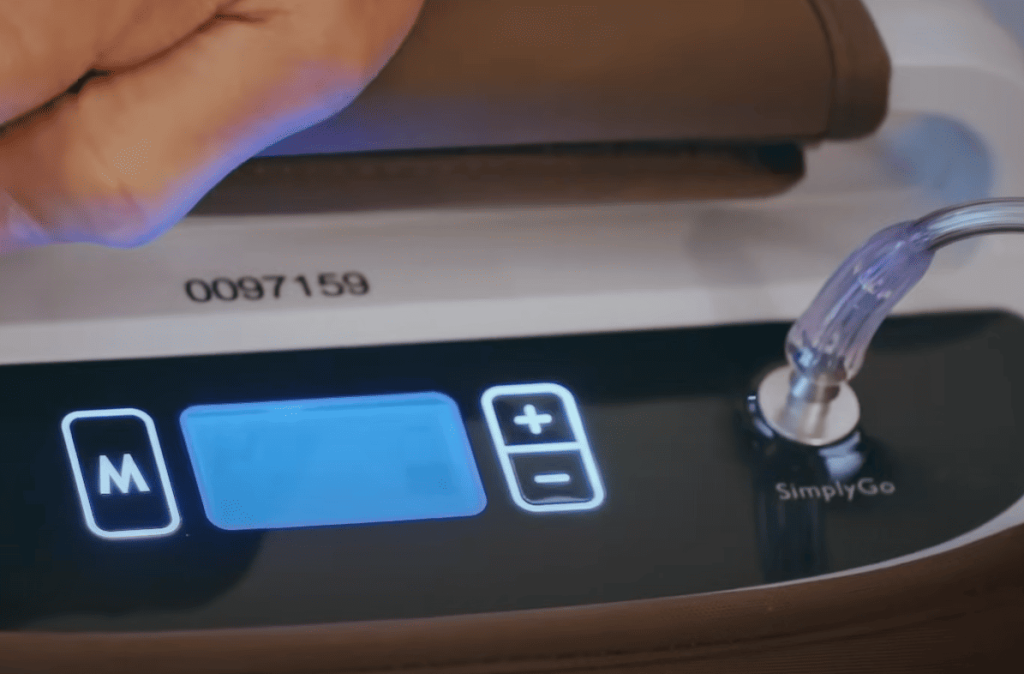

Manufacturer and Model Specific Error Insights

Medical devices come with their own instruction manuals hidden in digital alerts. While all machines prioritize safety, each manufacturer uses unique signals tailored to their model designs. Knowing these differences turns generic worry into targeted solutions.

MINNUO’s Smart Self-Help Features

MINNUO devices store troubleshooting answers behind their screens. Tap the “Help” menu to unlock:

- Multilingual code explanations

- Historical alert timelines

- Sensor calibration guides

Their PLC logging tracks patterns over weeks. “This feature helps technicians spot recurring issues during remote checks,” says a homecare specialist. Export these logs before calling your supplier – it speeds up repairs.

VARON’s Visual Warning System

VARON models pair specific beeps with color-coded lights. Their battery meter works like a phone charge display:

| Lights | Power Level | Action |

|---|---|---|

| 4 solid | ≥90% | Normal use |

| 1 flashing | <25% | Immediate charging |

Watch for breath detection alerts (F0002) on pulse-flow units. These ensure therapy matches your breathing rhythm. For purity drops:

- F0006 (yellow light): Check filters

- F0007 (flashing red): Contact assistance

“Manufacturer-specific information transforms users from passive observers to active partners in care.”

Routine Maintenance and Preventive Practices

Proactive upkeep is the unsung hero of medical equipment longevity. A smart maintenance schedule acts like an insurance policy – it prevents surprises while maximizing your device’s service years. Let’s explore two pillars of reliable operation: component care and data tracking.

Filter and Sensor Calibration Best Practices

Swap coarse filters every 2,000-3,000 hours – about 3-4 months of daily use. Fine filters last longer (4,000-6,000 hours), while desiccant packs need refreshing every 6-12 months. “Sticky notes on your device remind you when replacements are due,” suggests a homecare technician.

Calibrate sensors biannually using manufacturer tools. This ensures accurate readings for:

- Oxygen concentration levels

- Electrical flow stability

- Air pressure consistency

Maintaining a Record of Alarm Logs

Track alerts in spreadsheets or maintenance software. Categorize each entry as:

- False alarms (environmental triggers)

- On-site fixes (filter changes)

- Professional help needed (component failures)

Keep 3 feet of clearance around vents and use surge protectors. Voltage loggers catch dangerous power fluctuations – crucial for preventing sensor damage.

“Detailed records turn random beeps into actionable patterns. They’re your first clue when something’s brewing.”

Best Practices for Immediate Error Resolution

Mastering equipment care means knowing when to act and when to call experts. Simple fixes often involve checking parts you interact with daily. For example, water buildup in drains usually needs valve inspection, while minor purity changes might require cartridge checks.

Confident Self-Repair Decisions

Try these steps first: Clean clogged filters, ensure proper ventilation, and verify cable connections. Many alerts resolve with basic maintenance. If a temperature warning appears but stays within limits, cooling the unit often helps.

Recognizing Professional Help Needs

Persistent issues like screen freezes or repeated alerts demand expert assistance. Unusual codes (E98/F99) or electrical faults require trained technicians. “Safety first,” reminds a medical tech. “Some problems need specialized tools and knowledge.”

Keep a detailed log of all alerts and fixes. Note dates, solutions tried, and results. This documentation helps technicians diagnose faster and reveals patterns. Share these records during service calls – they’re golden for quick resolutions.

Remember: Quick action on simple issues prevents 70% of major repairs. But when in doubt, professional guidance protects both your health and equipment investment. Smart users balance DIY troubleshooting with knowing when to seek support.