Prepare to dive deep into the tangled wire of 3D printer stepper drivers, as this guide will unlock the enigma that is the dissimilarity between TMC2226 and TMC2209. With the rapid advancements in technology, it’s essential to stay up-to-date with the latest innovations in the realm of 3D printing. So, fasten your seatbelts, as you unravel the mysteries behind these two remarkable stepper motor drivers and explore the differences that set them apart. Whether you’re a seasoned enthusiast or a curious novice, this comprehensive guide will be your compass in navigating the complexities of TMC2226 and TMC2209.

What is 3D printing?

The 3D printing process involves a digital file being sent to the printer, which then prints out the desired object layer by layer in three dimensions. The digital file can be generated from various sources such as CAD software programs, digital scans, or even photographs. Once printed, the object can often be modified and further customized with additional layers of materials or colors.

The possibilities of 3D printing are endless, and the technology is being used in a wide variety of industries ranging from automotive to aerospace to medical devices. By utilizing 3D printing, companies can produce complex products that would be difficult or impossible to make using traditional manufacturing methods. Additionally, it has the potential to reduce waste and lower production costs for many businesses. It is an exciting and rapidly evolving technology that promises to revolutionize the way we create products in the future [1].

Advantages of 3D Printing

One of the main advantages of 3D printing is its ability to produce complex objects with greater speed and accuracy than traditional manufacturing methods. Additionally, it can reduce or eliminate many costly steps associated with manufacturing such as tooling and machining.

3D printing allows for greater customization of products, allowing for personalization with unique designs and shapes that would otherwise be too costly or time-consuming to create using other methods. It is also an environmentally friendly technology, as it produces less waste than traditional manufacturing processes. Finally, 3D printing can help reduce lead times by eliminating the need for long processes such as tooling and machining.

Another advantage of 3D printing is its potential to reduce costs for businesses. Since the process is faster and more efficient than traditional methods, it can cut down on production time and labor costs. Additionally, 3D printing eliminates many expensive steps such as tooling and machining, thus reducing overall costs. Finally, since objects are printed layer by layer, there is less material waste than with traditional methods.

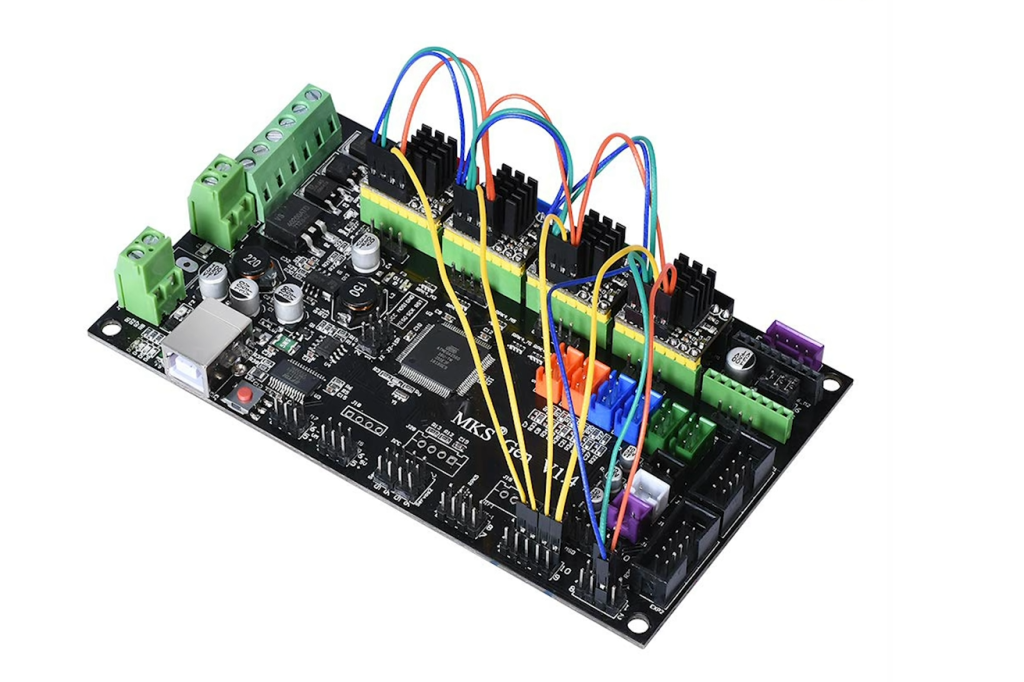

What drivers are used in 3D printing?

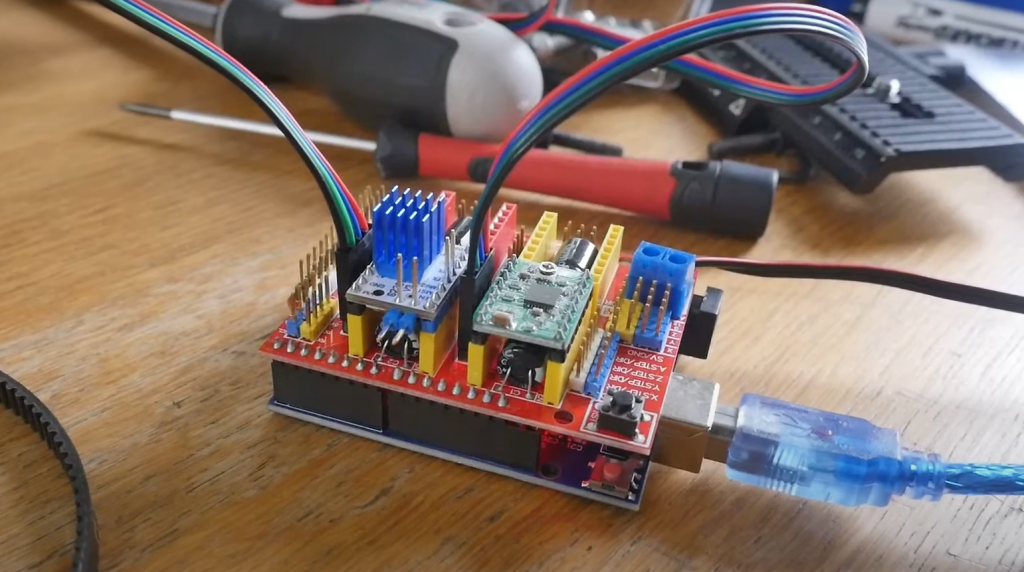

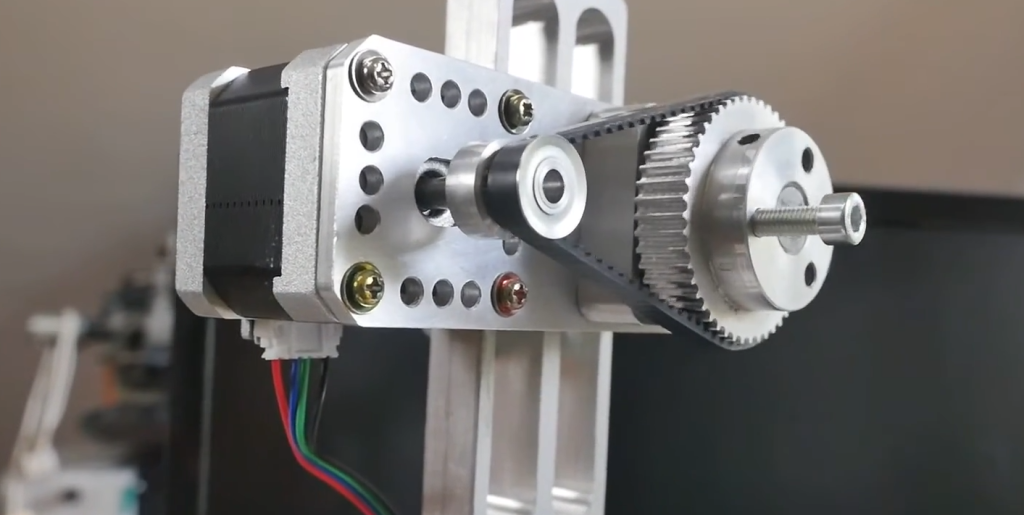

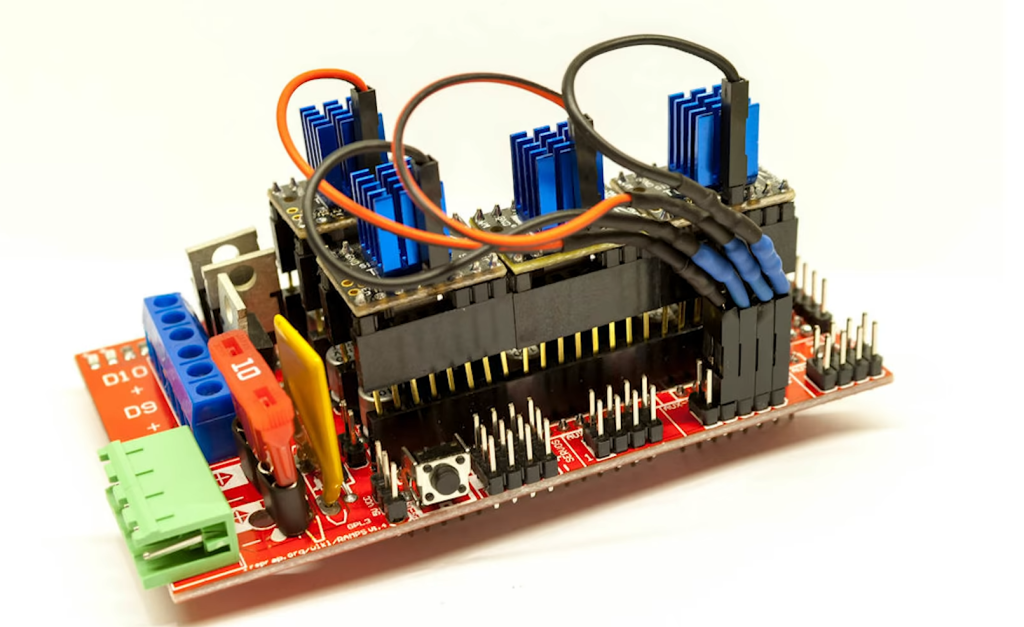

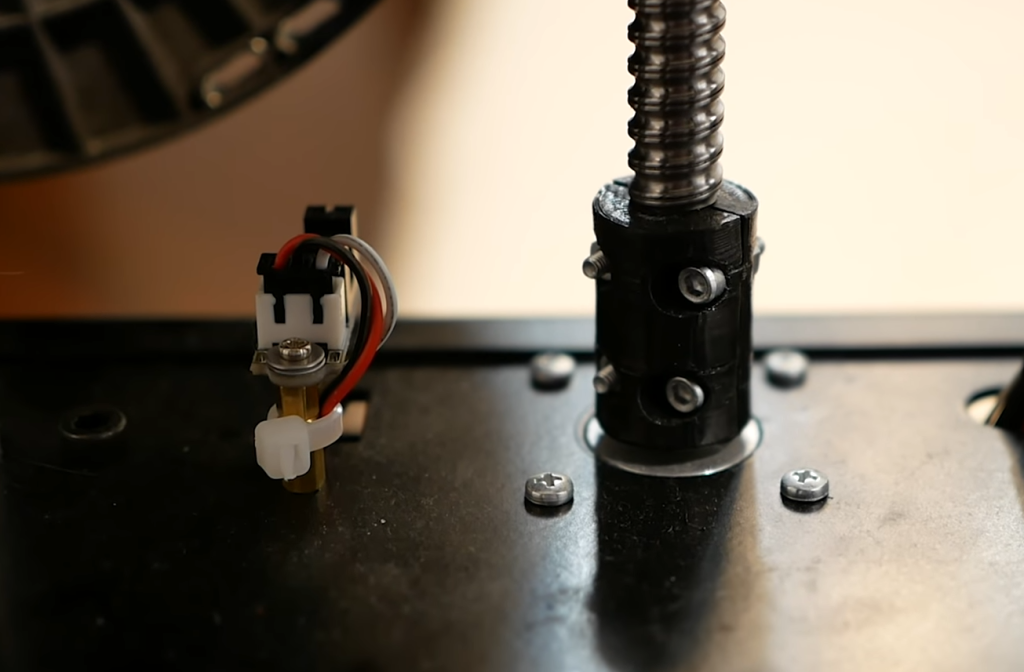

3D printing relies on drivers to move the printer’s axes and ensure precise movement of the printhead. Common types of 3D printing drivers include stepper motors, servo motors, and DC brushless motors. Stepper motors are typically used in small desktop 3D printers because they provide a low-cost solution with moderate torque capabilities. Servos motors are usually found in higher-end printers, where more precision is needed. Finally, DC brushless motors are typically used for large-scale industrial applications and provide the highest torque capabilities of all three.

Each driver type has its own advantages and disadvantages that should be taken into consideration when choosing which to use. Stepper motors are the most cost-effective option but generate a lot of noise due to their vibration. Servo motors have higher precision and accuracy but are more expensive than steppers. Finally, DC brushless motors offer the highest torque capabilities and require less maintenance than other types of drivers but come with a hefty price tag.

In addition to the type of driver used, it is also important to consider other factors such as resolution and speed when selecting a driver for 3D printing. Resolution refers to the smallest step size that can be taken by the motor and is usually measured in steps per inch (SPI). Speed, on the other hand, represents how quickly the driver can move from point A to B. Both of these factors will have a significant impact on overall print quality and should be taken into consideration when selecting a driver. Ultimately, the best driver for a given application will depend on the desired level of precision and speed, as well as budget constraints.

Overall, 3D printing relies on drivers to ensure precise movement of the printhead and enable high-quality prints. Different types of drivers are available, each with their own pros and cons that should be carefully considered when selecting a driver for a given application. Additionally, resolution and speed should also be taken into account to ensure the best possible results. With the right combination of driver type, resolution, and speed, high-quality 3D prints can be achieved without breaking the bank [2].

Technologies and patents for TMC drivers

StallGuard Technology

StallGuard is a patented technology developed by TMC that enables motor drivers to detect stall events in real-time. It works by measuring the back EMF of the motor and comparing it with a predetermined threshold. When the measured value surpasses this threshold, the driver can detect that the motor has stalled and take appropriate action. This technology is used in many applications such as robotics, CNC machines and 3D printers.

CoolStep Technology

CoolStep is another patented technology developed by TMC that helps motor drivers conserve energy. This technology works by dynamically changing the current level of the motor in order to reduce power consumption when the load is low. By using CoolStep, users can save up to 75% on their energy bill without compromising on performance. This technology is most suitable for applications where the load is constantly changing, such as in robotic arms and automated assembly lines.

SpreadCycle Technology

SpreadCycle is a patented TMC technology that allows motor drivers to operate at higher speeds while maintaining excellent torque control. This technology works by modulating the voltage applied to the motor coils in a spread-like pattern, resulting in higher torque and smoother operation. This technology is used in applications such as robotic arms and CNC machines that require high speed and accuracy.

MicroPlyer Technology

MicroPlyer is a patented TMC technology that enables motor drivers to control the current level of the motor with great precision. Using this technology, users can set the current level of the motor with a resolution as low as 1/256th of the full-scale value. This technology is most suitable for applications where high accuracy and precise control are required, such as 3D printing and laser cutting.

StealthChop technology

StealthChop is a patented TMC technology that allows motor drivers to operate in extreme silence. This technology works by modulating the voltage applied to the motor coils in a way that reduces noise and vibration, resulting in an exceptionally quiet operation. StealthChop is most suitable for applications where silent operation is desired, such as medical devices and automated robots.

DcStep technology

DcStep is another patented TMC technology that enables motor drivers to accelerate and decelerate with a minimum of power consumption. This technology works by modulating the voltage applied to the motor to limit the current drawn from the power supply. By using DcStep, users can save up to 50% on their energy bill without sacrificing performance. This technology is most suitable for applications where acceleration/deceleration control is required, such as robotic arms and automated assembly lines.

SensOstep technology

SensOstep is a patented TMC technology that enables motor drivers to detect and act upon changes in load conditions. This technology works by sensing the back EMF of the motor and comparing it with a predetermined threshold. When the measured value surpasses this threshold, the driver can detect that there has been a change in load condition and take appropriate action. This technology is used in many applications such as robots, CNC machines and 3D printers [3].

Operating modes (Step/Direction, SPI and UART)

Step/Direction mode

This operating mode is the most basic interface for controlling the stepper motor driver. It uses two input signals, step and direction, to control the speed and direction of the motor rotation. The Step signal is used to trigger a single pulse of motion in the desired direction while the Direction signal sets which way the motor will rotate when it receives a Step pulse.

SPI mode

The SPI interface allows for communication to the driver over a single, 4-wire connection. The SPI bus utilizes a master and slave setup where the user is considered the master and the driver is the slave. This setup allows for quick data transmission between devices with high precision timing due to its synchronous, clocked signal design. This mode of communication is optimal for applications requiring high-speed data transmission and precision timing.

UART mode

The UART interface provides a simple but efficient means for controlling the motor driver. It allows for full two-way communication between the user and the device over an asynchronous serial connection, making it more suitable for applications that require frequent updates or commands to be sent back and forth. The UART interface can also be used to directly control the motor driver without needing a host controller such as an Arduino or Raspberry Pi.

Differences between TMC2208 and TMC2209

Two of the most popular SilentStepSticks from Trinamic are the TMC2208 and the TMC2209. Although both offer similar features, there are several key differences between them.

In terms of power, the TMC2208 is rated up to 2A while the TMC2209 can handle up to 4A. Additionally, the TMC2208 has a maximum operating voltage of 36V while the TMC2209 supports up to 46V. Finally, the TMC2209 offers more protection against shorts, over-temperature and motor stall conditions compared to the TMC2208.

In conclusion, while both SilentStepSticks offer similar features, several key differences between them make one better suited for certain applications than the other. For those looking for higher power and more protection against shorts and over-temperature conditions, the TMC2209 is the ideal option. However, for those looking for higher torque and speed, the TMC2208 is a better choice. Whichever SilentStepStick you choose, it’s important to make sure that it meets your requirements before making a purchase. Thanks to the wide range of features offered by both TMC2208 and TMC2209 SilentStepSticks, there’s sure to be one that fits your needs.

FAQ

What is the difference between TMC2209 and 2660?

TMC2209 and 2660 are both stepper motor drivers designed for 3D printers, but they have some important differences. TMC2209 is a silent driver that uses StealthChop2 technology to reduce noise and offer smoother movement, while TMC2660 is the “traditional” stepper motor driver with more power but also more noise. The TMC2209 also has the benefit of a more compact design and better heat dissipation.

What are some of the advantages of using TMC2209 over 2660?

The main advantage of using TMC2209 is that it can offer smoother operation with less noise while still providing ample power for most 3D printing applications. Additionally, its compact design and better heat dissipation make it easier to install in smaller form factor machines. Finally, the TMC2209 is much more affordable than the TMC2660, making it a great option for those on a budget.

What type of stepper motor should I use with TMC2209?

TMC2209 is compatible with most types of stepper motors, including 1.8° and 0.9° hybrid steppers, as well as 2-phase and 4-phase motors. In general, it is recommended to use a motor with an inductance of at least 3 mH for optimal performance with the TMC2209 driver. It is also important to make sure that your motor is rated for the same voltage as your driver.

Do I need to use a heatsink with TMC2209?

It is not necessary to use a heatsink with TMC2209, but it can help if you are running your system at high currents or in a very hot environment. A small heatsink can provide additional cooling and reduce the risk of overheating. Additionally, it is important to make sure that there is adequate airflow around the driver and motor for proper cooling.

What should I do if my TMC2209 driver is not working?

If your TMC2209 driver is not working correctly, the first step should be to check all connections and make sure everything is properly connected. Additionally, check the settings in the firmware and make sure that they are configured correctly for your setup. If all else fails, you can try resetting the driver by shortening the pins on the back of the driver and then re-flashing your firmware. If none of these steps resolve the issue, you may need to replace or repair your TMC2209 driver.

How do I update the firmware on my TMC2209 driver?

Updating the firmware on your TMC2209 driver is relatively simple and can be done with a USB to TTL serial adapter. First, you will need to download the latest version of the firmware from the manufacturer’s website. Connect your serial adapter to both your computer and TMC2209, then open the firmware file in a compatible software program. Finally, click the “Write” button to flash the new firmware onto your driver. Once the process is complete, you can disconnect everything and your TMC2209 will be up and running with the latest version of the firmware.

What is the difference between TMC2225 and TMC2226?

The TMC2225 and TMC2226 are both stepper motor drivers designed for 3D printers, but they have a few key differences. The main difference is that the TMC2225 has a built-in microstep interpolation circuit which allows for smoother movement at higher speeds, while the TMC2226 does not. Additionally, the TMC2225 has a higher current rating and can handle up to 2.5A of RMS current, while the TMC2226 can only handle up to 1.2A of RMS current. Finally, the TMC2225 is more expensive than the TMC2226, making it better suited for high-performance applications that require greater power and precision.

Conclusion Paragraph

TMC2226 and TMC2209 3D printer stepper drivers are two of the most popular choices for controlling a 3D printer’s movement. Both models provide high performance, excellent thermal management, and reliable operation. The TMC2226 has more current capacity than the TMC2209, and can be used to control up to 8 motors at once, while the TMC2209 can only handle up to 4 motors. The TMC2226 also offers down-step stall detection, which helps to prevent the motor from stalling and damaging itself. Additionally, the TMC2226 is more expensive than the TMC2209 but its higher performance makes it a better choice for 3D printer applications that require precision movement or multiple motors.

Useful Video: Trinamic TMC2209 silent Stepper motor vs. traditional stepper motor driver (VERY SILENT!!!)

References:

- https://3dprinting.com/what-is-3d-printing/

- https://themachinebros.com/basic-guide-of-3d-printer-stepper-motor-drivers/

- https://3dwork.io/en/tmc-drivers/