When it comes to achieving maximum efficiency in electronic devices, one component that often plays a crucial role is the feedthrough capacitor. But wait, you may be asking yourself, what is a feedthrough capacitor? Well, buckle up because this blog post is about diving deep into the world of feedthrough capacitors and uncovering their secrets for unleashing the full potential of your electronic creations. Prepare to be amazed as this guide will unravel the mysteries and show you how to harness the power of these mighty capacitors to take your devices to new heights. So, whether you’re a curious beginner or a seasoned expert, get ready to embark on a journey that will revolutionize the way you think about efficiency in electronic design.

What is a Feedthrough Capacitor?

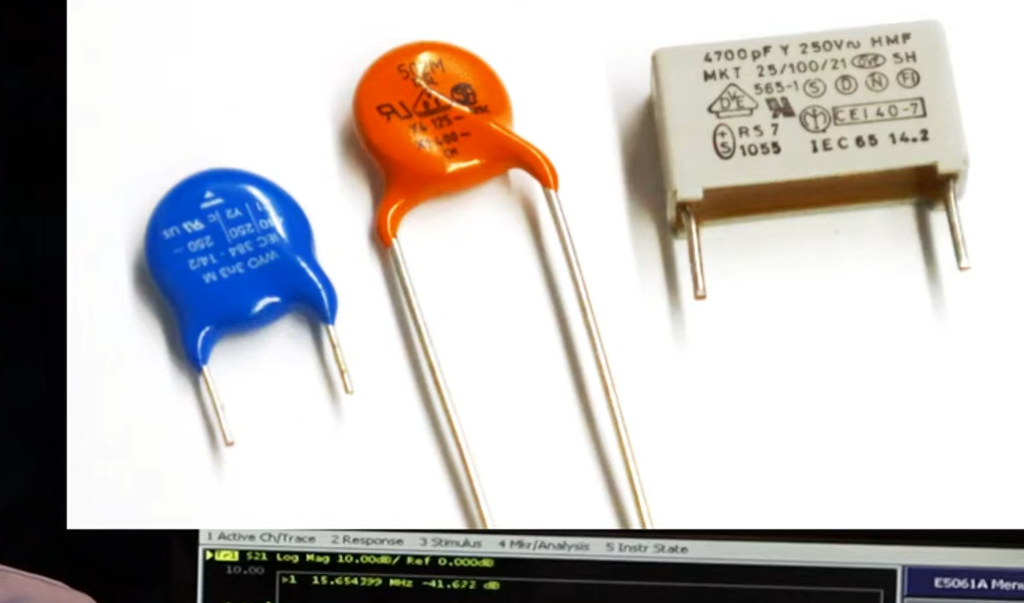

Feedthrough capacitors are manufactured using a variety of materials, such as ceramic, tantalum and polyethylene. Each type has its own unique properties, allowing them to be used for specific applications. For instance, ceramic feedthrough capacitors are typically used in high-power RF applications due to their excellent dielectric properties and low cost. On the other hand, tantalum feedthrough capacitors are preferred for audio applications due to their high signal quality.

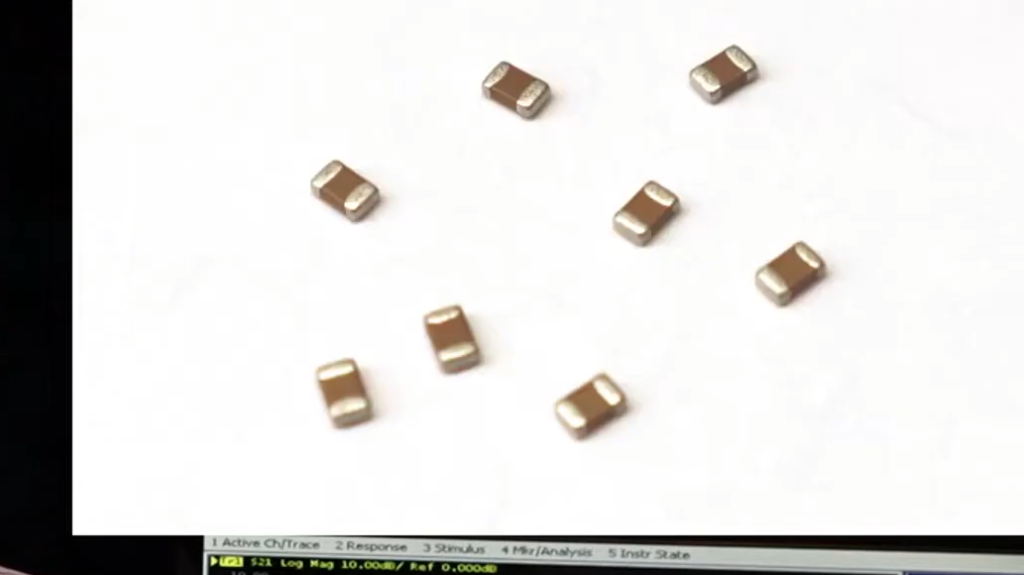

Feedthrough capacitors come in a wide range of sizes, shapes and configurations. They can be as small as 0201 packages or as large as 50mm packages. In addition, they can have either through-hole or surface mount terminations, allowing them to be used on both PCBs and other substrates.

Feedthrough capacitors are an essential component for any electrical system, as they provide both AC and DC filtering. This makes them ideal for applications that require high levels of signal integrity or noise reduction. Furthermore, they are relatively inexpensive and easy to install, making them a great addition to any design. As such, feedthrough capacitors continue to be popular in many types of electronic circuits.

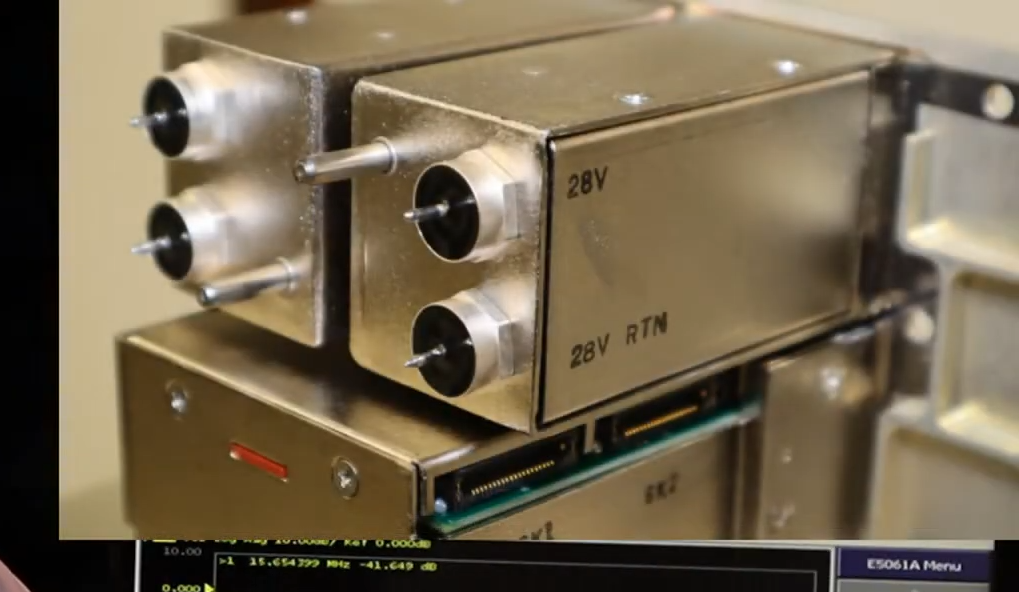

In addition to their use in RF and audio applications, feedthrough capacitors are also used to create ground loops for power supplies. By connecting a capacitor between the two points, the current can be directed away from the signal path, thus reducing any unwanted interference. This type of application is particularly important in medical equipment, as it helps reduce the risk of patient harm due to electrical shock [1].

Feedthrough Capacitors Classification

C type

C-type feedthrough capacitors are typically small, tubular components that offer an efficient way to pass DC current through a circuit. They have two metal layers separated by a dielectric material, with the dielectric typically being either ceramic or plastic. The two metal layers act as plates of a capacitor, blocking any AC signal from passing through while allowing DC current to pass. C-type feedthrough capacitors are commonly used in consumer electronics, such as computers and cell phones, for bypassing electric charges between circuit components.

S type

S-type feedthrough capacitors also have two metal layers separated by a dielectric material, but the layers are arranged differently than with C-type feedthrough capacitors. The dielectric is typically either ceramic or plastic, but different types of metals are used for the two layers of metal. S-type feedthrough capacitors can block both AC and DC signals from passing through and are most often used in industrial applications, such as motors and pumps.

D type

D-type feedthrough capacitors are similar to C-type and S-type feedthrough capacitors in that they have two metal layers separated by a dielectric material. However, the two layers of metal are arranged differently than with either C- or S-type feedthrough capacitors. The dielectric is typically ceramic, and the two layers of metal can be either aluminum or steel. D-type feedthrough capacitors are commonly used in communications systems, such as satellite dishes and antennas, for blocking RF signals from passing through while allowing DC current to pass.

L type

L-type feedthrough capacitors are similar to D-type feedthrough capacitors, but they have a different arrangement of the two metal layers. The dielectric is typically ceramic or plastic, and the two layers of metal can be either aluminum or steel. L-type feedthrough capacitors are most often used in high-frequency applications, such as in cellular phones and wireless networks, for blocking RF signals from passing through while allowing DC current to pass.

Pi Type

Pi-type feedthrough capacitors are very similar to L-type, but they have a different arrangement of the two metal layers. The dielectric is typically ceramic or plastic, and the two layers of metal can be either aluminum or steel. Pi-type feedthrough capacitors are commonly used in medical devices, such as pacemakers and implantable defibrillators, for blocking RF signals from passing through while allowing DC current to pass [2].

Characteristics and Applications of Feedthrough Capacitors

Solder-type feedthrough capacitor

The solder-type feedthrough capacitor is one of the most common types of feedthrough capacitors. It consists of a metal core and two leads attached to each end. The leads are then soldered onto the PCB or other electrical component. This type of capacitor has a wide range of applications, including filtering noise from power supplies, coupling signals between stages, and providing decoupling in radio frequency circuits.

Surface mount feedthrough capacitor

Surface mount feedthrough capacitors are similar to solder-type capacitors but feature a flat and thin construction. This allows them to be mounted on the surface of the printed circuit board, eliminating the need for soldering. They are commonly used in high-frequency applications, as they provide superior signal integrity and isolation, as well as greater stability than other types of capacitors.

Resin-sealed threaded feedthrough capacitors

Resin-sealed threaded feedthrough capacitors are another popular type of feedthrough capacitor. This type features a metal core with two electrodes, each covered with a layer of resin. The electrodes are then securely threaded into the PCB or other component for a tight fit. These types of capacitors provide excellent signal isolation and stability, making them ideal for high-frequency applications such as RF circuits.

Film feedthrough capacitor

The film feedthrough capacitor is a thin-film type of capacitor. It consists of two metal plates with an insulating film layer between them. This type of capacitor has excellent high-frequency characteristics, making it ideal for high-frequency applications such as RF filters, oscillators, and amplifiers. It also has superior temperature stability compared to other types of capacitors.

Ceramic feedthrough capacitor

The ceramic feedthrough capacitor is a type of capacitor that uses ceramic material as the dielectric layer. This type of capacitor has low ESR (equivalent series resistance) and high capacitance values, making it ideal for high-frequency applications. It also has excellent temperature stability and is relatively inexpensive compared to other types of capacitors. In addition, ceramic feedthrough capacitors are often used in high-power applications due to their ability to handle large current surges without damage.

High current and high voltage resin-sealed feedthrough capacitors

High current and high voltage resin-sealed feedthrough capacitors are a specialized type of feedthrough capacitor that is designed to handle large amounts of current or voltage. These types of capacitors feature a robust construction with an insulating layer between the electrodes to help protect against electrical arcing. They are often used in power supply circuits, motor control circuits, and other high-voltage and high-current applications.

Glass-sealed high-performance feedthrough capacitors

Glass-sealed high-performance feedthrough capacitors are a specialized type of capacitor that is designed to offer superior performance in high-frequency applications. This type of capacitor has an insulated glass layer between the electrodes, which helps to reduce noise and improve signal integrity. They also have excellent temperature stability and can handle large surge currents without damage. Glass-sealed feedthrough capacitors are commonly used in RF circuits and other high-frequency applications [3].

5 types of feedthrough filters

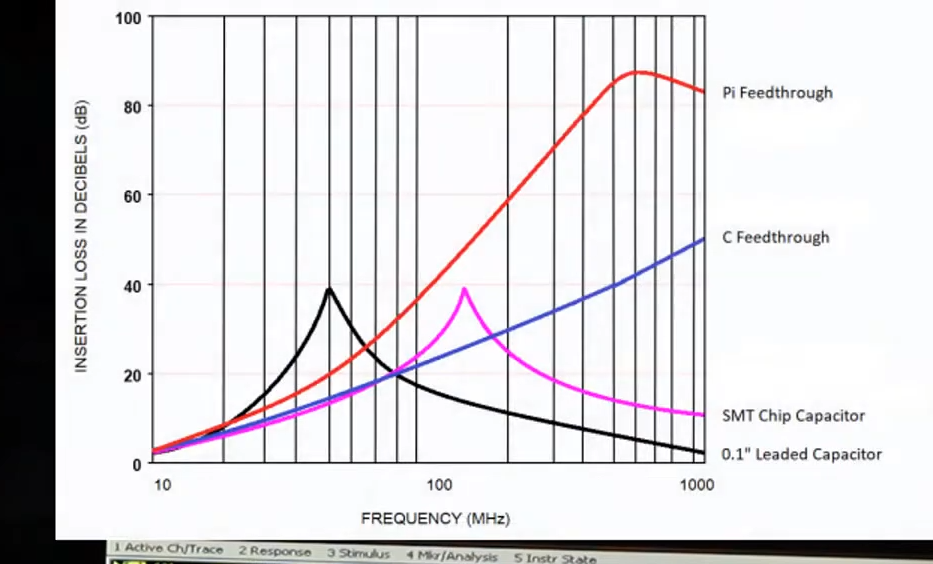

C-type filter

A C-type filter, also known as a feedthrough filter, is the most commonly used type of filter in various electronic circuits. Its design features a cylindrical metal shield that encloses two or more capacitor plates, which are connected to the input and output wires of the circuit.

This configuration not only ensures effective suppression of electromagnetic interference (EMI), but also provides enhanced performance and reliability. By effectively filtering out unwanted noise and disturbances, C-type filters help to maintain signal integrity and prevent potential issues in electronic systems.

However, it is important to note that C-type filters do come with some drawbacks. Compared to other types of filters, they tend to be more expensive and complex to implement. Despite these considerations, the superior EMI suppression capabilities and overall performance make C-type filters a preferred choice in many applications requiring stringent noise control and signal integrity.

LC-type filter

An LC-type filter is a specialized variation of the C-type filter commonly used in electronic circuits. It is designed to provide even higher levels of attenuation for very high-frequency signals by incorporating an inductor in addition to the capacitors. This combination of components allows the filter to effectively suppress unwanted noise and interference, ensuring cleaner and more reliable signal transmission.

However, it’s important to note that the increased performance of LC-type filters comes at a cost. Due to the added complexity and size of the inductor, these filters require more precise tuning during the installation process. This can be a challenge for engineers and technicians, as it demands careful adjustment to achieve optimal filtering characteristics.

Despite these challenges, the benefits of using LC-type filters are undeniable. Their ability to effectively reduce high-frequency noise makes them a valuable tool in many applications, such as audio systems, radio receivers, and communication devices. By incorporating an LC-type filter into a circuit design, engineers can ensure superior performance and enhance the overall functionality of their electronic systems.

T-Type Filters

T-type filters are commonly employed in low-power applications, specifically in automotive and consumer electronics. These versatile filters excel at effectively attenuating both high and low-frequency signals, ensuring optimal signal quality. However, it is important to note that T-type filters may have some limitations when it comes to achieving higher levels of attenuation. Despite this, their widespread usage and reliable performance make them a popular choice in various industries.

Double T filters

Double T filters, also referred to as dual-mode filters, are advanced variations of the T-type filter. These filters employ the use of two capacitors, along with an inductor, to create a highly efficient bandstop filter. With this design, double T filters are capable of delivering exceptional attenuation levels for both high and low-frequency signals, making them ideal for applications that require precise signal filtering. The combination of capacitors and inductors in a double T filter allows for enhanced control over the filtering characteristics, enabling engineers to tailor the filter response according to specific requirements. This versatility makes double T filters a valuable tool in various industries, including telecommunications, audio processing, and electronic instrumentation.

Structure and Usage of Feedthrough Capacitors

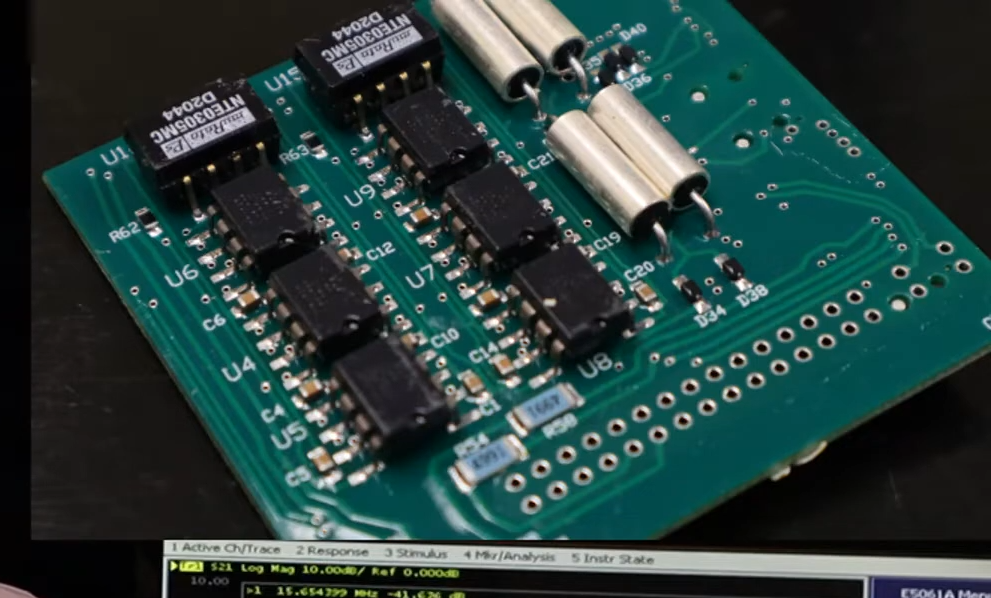

Feedthrough capacitors have several unique structures, each with its own advantages and disadvantages. For instance, the most common type is the radial-leaded capacitor, which has two opposing prongs that fit into holes in the board and are soldered into place. This structure offers low inductance and high-frequency response, as well as ease of installation. However, it is prone to vibration and temperature shifts, which can cause the capacitor to become loose in its mounting.

Another popular type of feedthrough capacitor is the surface-mount capacitor. This type offers a smaller footprint than the radial leaded version, as well as improved thermal stability. However, these capacitors are more susceptible to noise due to their proximity to other components.

Finally, the chip feedthrough capacitor provides the highest degree of high-frequency performance and noise reduction, but it is more difficult to install than other types. Additionally, it requires careful soldering techniques to ensure proper installation.

Regardless of the type chosen, feedthrough capacitors are an important component in many electronic devices, allowing them to work efficiently and reliably without extra interference. In many cases, selecting the right capacitor for a particular application can be a matter of trial and error, as each type has its own set of advantages and disadvantages. It is important to do research on different types before purchasing to get the best results.

FAQ

What is the difference between a feed-through capacitor and a capacitor?

A feed-through capacitor is a type of capacitor specifically designed to reduce or eliminate EMI/RFI interference when placed in a circuit. It is usually connected between the power source and the ground. Unlike regular capacitors, which are generally used for filtering and energy storage applications, a feed-through capacitor has special design features that allow it to effectively block out unwanted signals. As such, it is often used in applications where EMI or RFI interference needs to be reduced.

How does a feed-through capacitor work?

A feed-through capacitor works by providing an impedance between the power source and the ground, which helps to reduce or block out EMI/RFI interference. It acts as a two-way filter, allowing high-frequency signals to pass through while blocking low-frequency noise. The capacitor also acts as a capacitor bank, which helps to store energy and provides an additional layer of protection against power surges. Additionally, the feed-through capacitor can be used in combination with other components such as inductors or ferrite beads to further reduce unwanted interference.

What is the purpose of the feedthrough?

The main purpose of a feed-through capacitor is to reduce or block out EMI/RFI interference in order to improve the signal quality and reliability of the circuit. By providing an impedance between the power source and the ground, it helps to filter out unwanted signals while allowing desirable ones to pass through. Additionally, by acting as a capacitor bank, it also provides additional protection against power surges.

Are there any drawbacks to using a feedthrough capacitor?

One of the main drawbacks of using a feed-through capacitor is that it can reduce the signal strength of desirable signals, which can lead to decreased performance in certain applications. Additionally, if not installed correctly, it can cause increased power consumption and create additional noise in the circuit. As such, it’s important to ensure that the capacitor is correctly installed and that its parameters are properly adjusted in order to maximize its effectiveness.

What precautions should be taken when installing a feed-through capacitor?

When installing a feed-through capacitor, it is important to ensure that the correct type of capacitor is being used for the application. Additionally, all power and ground connections should be checked for correct polarity before the capacitor is connected. The capacitor should also be properly secured to prevent any movement or vibration due to mechanical stresses. Finally, it’s important to ensure that the parameters of the feed-through capacitor are correctly adjusted in order to maximize its effectiveness.

What type of applications are best suited for using a feed-through capacitor?

Feed-through capacitors are most commonly used in applications that require high levels of EMI/RFI protection, such as medical equipment, automotive electronics, and military systems. Additionally, they can also be used in audio/video applications to reduce noise and improve signal quality. In general, any application where high levels of interference need to be reduced or eliminated can benefit from the use of a feed-through capacitor.

Are there any alternatives to using a feed-through capacitor?

In some cases, other components such as inductors or ferrite beads might be used in place of a feed-through capacitor in order to reduce EMI/RFI interference. Additionally, it is also possible to incorporate shielding in the design of the circuit in order to reduce interference. However, these methods often do not provide as much protection as a feed-through capacitor and should only be used if absolutely necessary.

What is a feedthrough filter?

A feedthrough filter is a type of device that is used to reduce or eliminate EMI/RFI interference in electronic circuits. It consists of a capacitor connected between the power source and the ground, which helps to filter out unwanted signals while allowing desirable ones to pass through. Additionally, it can also be used in combination with other components such as inductors or ferrite beads to further reduce interference. Feedthrough filters are often used in applications where high levels of EMI/RFI protection is required, such as medical equipment, automotive electronics, and military systems.

What are the 3 terminals of an AC capacitor?

The three terminals of an AC capacitor are the common terminal (C), the positive terminal (P), and the negative terminal (N). The common terminal is typically connected to the power source, while the positive and negative terminals are used to connect the capacitor to other components in the circuit. In certain applications, such as motor starting circuits, it may also be necessary to use multiple capacitors connected in series or parallel in order to achieve the desired effect. For more information, please consult an experienced electrical engineer.

Why does a capacitor have 4 terminals?

A capacitor with four terminals is typically a type of feed-through capacitor, which is designed to reduce or eliminate EMI/RFI interference when placed in a circuit. It consists of two capacitors that are connected in series and have three external connections (positive, negative, and common) as well as an internal connection between the two capacitors. This design allows the capacitor to provide an impedance between the power source and ground, which helps to reduce or block out EMI/RFI interference. Additionally, it can also be used in combination with other components such as inductors or ferrite beads to further reduce unwanted noise.

What is a bypass capacitor?

A bypass capacitor is a type of capacitor that is connected in parallel with a component or circuit to provide a low-impedance path for certain frequencies. It acts as a short circuit at those frequencies, allowing them to bypass the main circuit and travel directly to the ground without being affected by other components. Bypass capacitors are often used in high-frequency applications where it is necessary to reduce EMI/RFI interference, as they can help filter out unwanted signals while allowing desirable ones to pass through. Additionally, they can also be used in power supplies and voltage regulation circuits to reduce ripple noise and improve system stability.

Conclusion Paragraph

In conclusion, feedthrough capacitors are an important component in many electronic applications and can be found in a variety of systems. They offer many advantages, such as improved performance, lower cost, higher reliability, and smaller size. By understanding the different types available and their associated features, designers can select the best feedthrough capacitors to optimize their system performance. Additionally, designers need to take into account the physical size and limitations of their application when selecting feedthrough capacitors. With the right selection, feedthrough capacitors can provide a great solution for many electronic applications.

Useful Video: Advantages of Feedthrough Style EMI Filters

References:

- https://www.utmel.com/blog/categories/capacitors/what-is-feedthrough-capacitor

- https://www.jotrin.com/technology/details/what-is-feedthrough-capacitor

- https://passive-components.eu/feedthrough-capacitors-technology-and-applications/