In a world where technology reigns supreme, there are hidden wonders that power our devices and keep them buzzing with life. One such marvel is the enigmatic flyback transformer. Shrouded in mystery, this seemingly ordinary component holds the key to unlocking a realm of possibilities. From their inception to their inner workings, this article will leave no stone unturned in the quest to decode the magic behind these captivating devices. Prepare to be mesmerized as you delve into the fascinating world of flyback transformers and learn what makes them truly extraordinary.

What is the purpose of a flyback transformer?

The transformer also helps provide a steady voltage level, which is especially important in high-frequency and low-power applications. In addition to these functions, the flyback transformer can be used to create a resonant circuit for frequency control or for pulse width modulation of the output waveform. Finally, it can be used to generate higher voltages for some applications. In sum, flyback transformers are an essential part of many power supplies and can provide several key benefits.

One potential problem with the use of flyback transformers is that they often produce high levels of electromagnetic interference (EMI). EMI is caused by the sudden switching of electrical currents within the transformer, which creates a large amount of electrical noise. Proper shielding of the transformer can help reduce this noise, although it is not always possible to eliminate it. As such, some flyback transformers are designed with EMI suppression built into them, which helps reduce the amount of interference that is produced.

Furthermore, the construction of a flyback transformer needs to be carefully planned to avoid any potential safety hazards. If components are not correctly spaced, the transformer can overheat and cause a fire hazard. It is also important to use appropriate insulation materials to prevent electric shock or other risks. Overall, understanding the purpose of the flyback transformer and taking precautionary measures is essential for its safe and efficient operation [1].

Introduction To Flyback Transformer

Design of Flyback Transformer

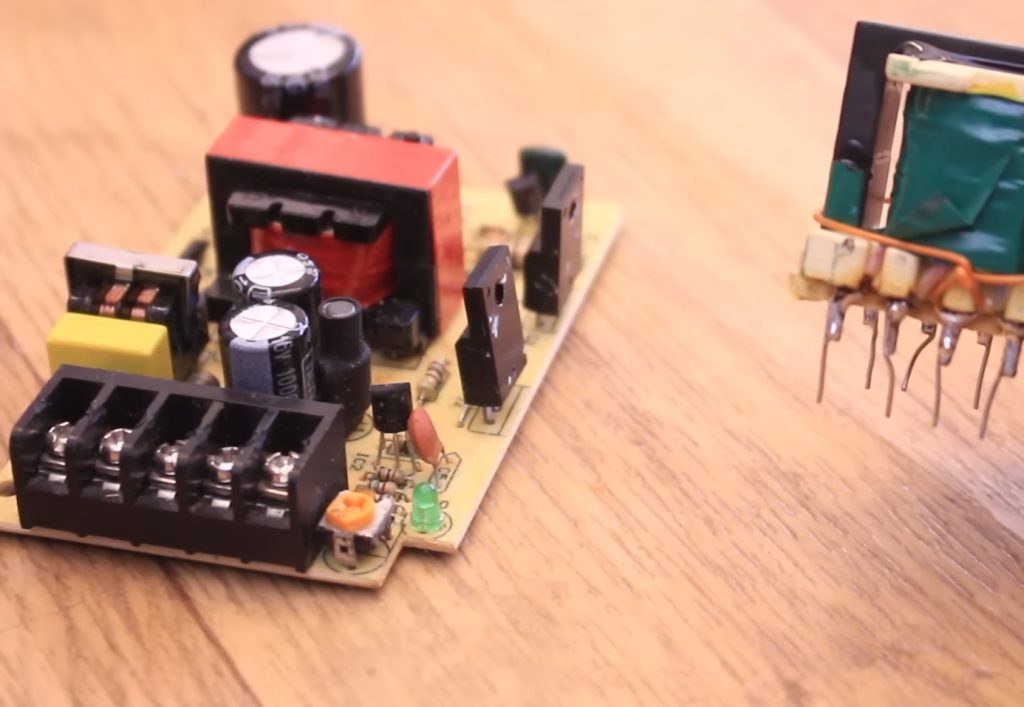

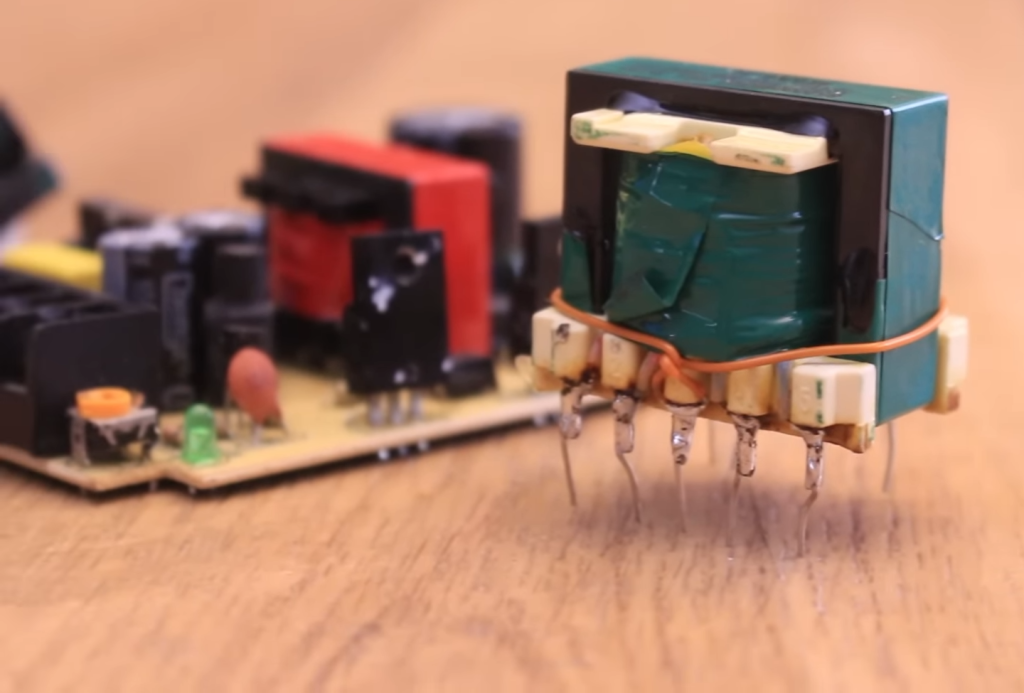

The flyback transformer is an ideal choice for applications such as switching power supplies, LED drivers, and high-voltage inverters. It is designed to convert AC input into DC output with minimal losses. The core of the flyback transformer consists of ferrite or silicon steel laminations arranged in a bobbin and wound with insulated wire. There are two types of windings used in this type of transformer: the primary winding and the secondary winding. The primary winding is responsible for carrying the input voltage while the secondary winding carries the output voltage.

The design of a flyback transformer is based on several parameters such as core size, number of turns, wire gauge, thickness of insulation, and operating frequency. These parameters determine how much power the transformer can handle, as well as its efficiency and overall performance. The primary winding is typically designed to have a higher number of turns than the secondary winding since it carries higher voltage and current. Additionally, the insulation used for the windings should be thick enough to reduce losses due to eddy currents.

Working principle of Flyback Transformer

The working principle of the flyback transformer is based on Faraday’s law of induction. Essentially, when an AC voltage is applied to the primary winding, a magnetic field is created which induces voltages in the secondary winding. The magnitude of this induced voltage depends on several factors such as the number of turns in each winding, core size, and frequency of operation.

The flyback transformer also takes advantage of the “flyback” phenomenon, which occurs when the magnetic field collapses after the AC input is removed. This causes a voltage spike in the secondary winding, which can be used to generate high voltages for applications such as LED drivers and inverters.

Current when switched off

When the flyback transformer is switched off, it stores energy in the form of a magnetic field generated by the inductor. This magnetic field is an essential part of the transformer’s operation, but when it collapses, it can produce a sudden change in current known as a current spike. These current spikes can be detrimental to sensitive electronic components, potentially causing damage if not properly managed.

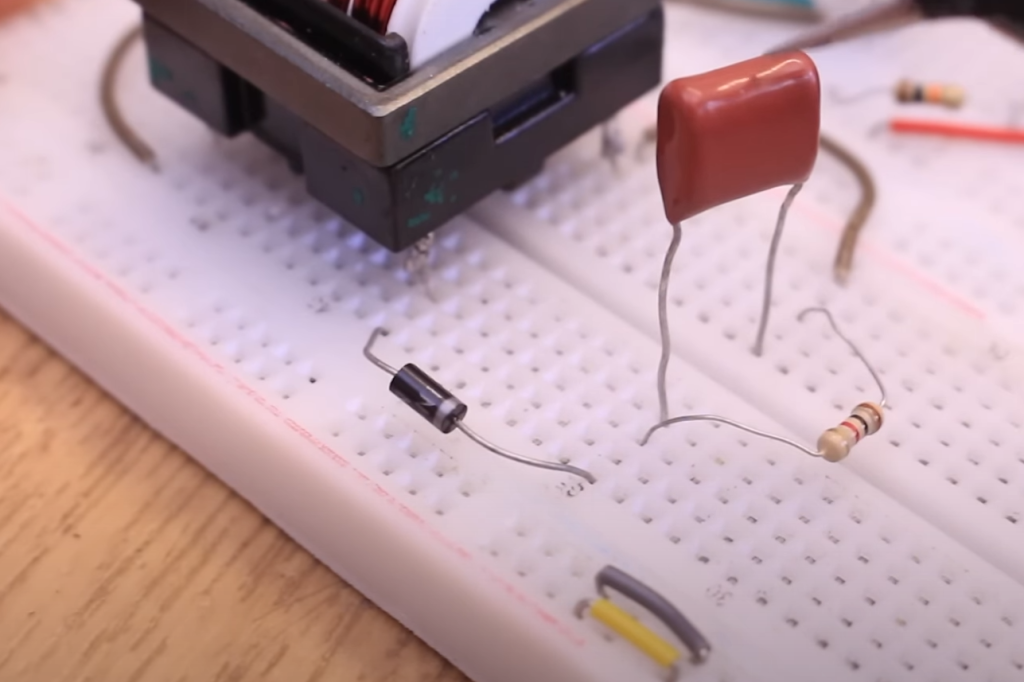

To mitigate the risk of damage, designers often incorporate snubber circuits or capacitors into the circuit. These components are strategically placed to absorb excess energy and prevent it from reaching the delicate electronic components. By dissipating the stored energy, the snubber circuit or capacitor acts as a buffer, protecting the circuit from the harmful effects of current spikes.

In addition to snubber circuits, diodes can also play a role in reducing voltage spikes. By providing a designated path for the current, diodes allow for controlled dissipation of energy and prevent sudden increases in voltage. This helps to maintain a stable and safe operating environment for the electronic components.

By implementing these measures, designers can effectively manage the energy stored in the flyback transformer, ensuring the protection of sensitive electronic components and prolonging the overall lifespan of the circuit.

Advantages and Disadvantages

The flyback transformer offers several advantages over other topologies such as reduced size, low cost, and high efficiency. Additionally, it is relatively easy to design since most of the parameters are pre-determined. However, there are also some drawbacks to using this topology. For example, the high current spikes when the transformer is switched off can damage sensitive components if not properly managed. Additionally, the design parameters must be carefully chosen to ensure optimal efficiency and performance.

Overall, the flyback transformer is a popular choice for applications such as LED drivers and high-voltage inverters due to its low cost, small size, and high efficiency. With careful design considerations, it can be an ideal solution for these applications.

Applications of Flyback Transformer

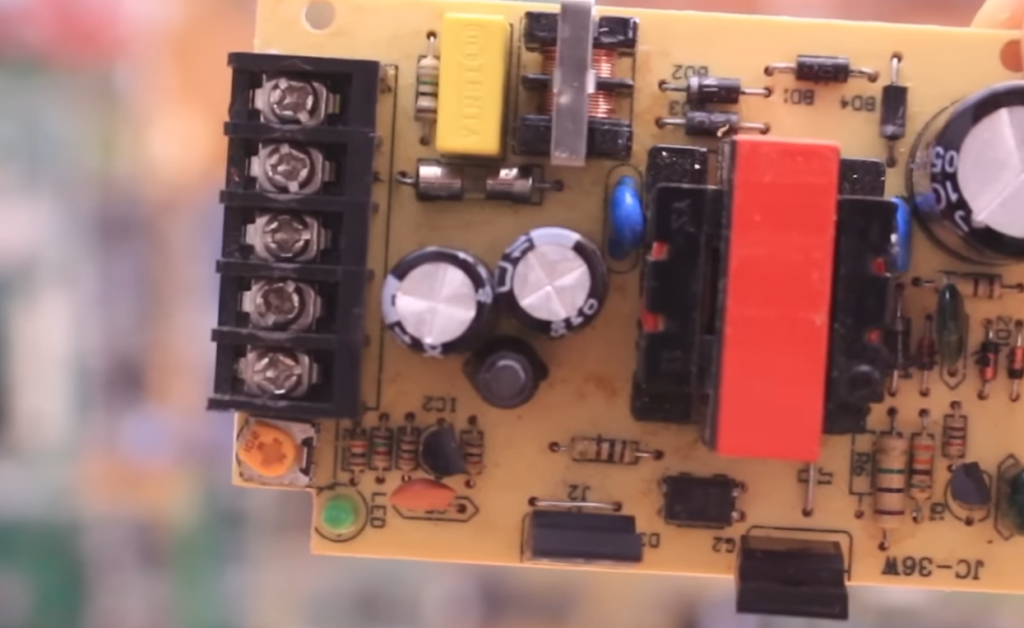

The flyback transformer is a versatile component that finds wide-ranging applications in various fields. It is commonly used in switching power supplies, LED drivers, inverters, DC-DC converters, and high-voltage circuits. In the automotive industry, the flyback transformer plays a crucial role in ignition systems, voltage regulators, and alternators. Moreover, it proves invaluable in medical devices like X-ray machines and defibrillators, where it generates high voltages with precision and reliability. With its cost-effectiveness and exceptional efficiency, the flyback transformer emerges as the go-to choice for a diverse array of applications in different industries. Its adaptability and performance make it an indispensable asset in today’s technological landscape.

Safety Considerations

When working with flyback transformers, it is crucial to be aware of their potential to generate high voltages, which can pose a significant danger if not handled properly. To ensure safety, it is imperative to implement appropriate measures such as using insulated wiring to prevent electrical shocks, incorporating overload protection to safeguard against excessive current, and installing ground fault interrupters to detect and prevent electrical hazards. Moreover, designing the flyback transformer correctly is of utmost importance to achieve both optimal performance and safety. By paying close attention to these key aspects, the risks associated with flyback transformers can be effectively mitigated, ensuring a secure working environment [2].

How does a Flyback Converter work?

Charging Phase – Switch Closed

The Flyback converter, a widely used power conversion topology, initiates its cycle in the charging phase. In this phase, a switch (typically a transistor) is closed, allowing current to flow through the primary winding of the transformer. As the current gradually accumulates in the primary winding, it gives rise to an augmented magnetic flux within the core. This increasing magnetic flux not only stores energy but also gradually builds up to its peak value, thus facilitating efficient energy transfer within the converter.

Discharging Phase – Switch Open

Once the peak magnetic flux value is reached, the switch opens and the current in the primary winding rapidly falls to zero. This sudden interruption of current flow causes a significant voltage spike across the primary winding, resulting from the inductance of the circuit. As a consequence, this voltage spike induces a corresponding voltage and associated current in the secondary winding of the transformer. It is important to note that this energy, previously stored as magnetic flux in the transformer’s core, now becomes readily available as output voltage and current in the secondary winding. Subsequently, this voltage and current are efficiently transferred to the load, ensuring the smooth and effective operation of the system.

Regenerative Action

During the discharging phase, as the magnetic flux gradually decreases, it eventually reaches zero and undergoes a polarity reversal. This reverse cycle triggers a regenerative action within the transformer core, causing its magnetic field to change direction. This intriguing phenomenon can lead to additional energy transfer from the primary to the secondary (or vice versa) before the cycle comes to a close. The interplay between magnetic flux, polarity reversal, and energy transfer showcases the complex dynamics at play within the transformer during this phase.

Energy Transfer Efficiency

The overall efficiency of the Flyback converter depends on a variety of factors. These factors include the core material, size of the core, and the inductance and resistance values of the primary and secondary windings. Additionally, the characteristics of the switch used in the converter also contribute to its efficiency. Another important factor to consider is the switching frequency. Generally, higher frequencies tend to result in higher efficiency for the Flyback converter. By carefully considering and optimizing these design choices, it is possible to achieve remarkably high levels of energy transfer efficiency with the Flyback converter [3].

How to use a Flyback Transformer?

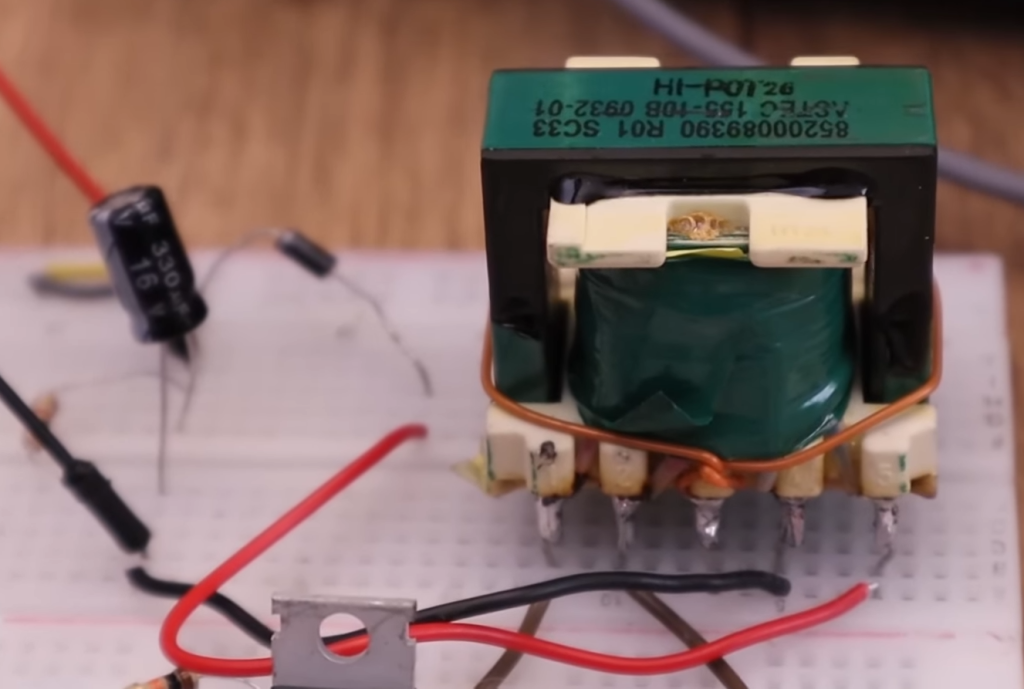

Next, the user will need to connect all the necessary components to the transformer, including wires, capacitors, and resistors as applicable. Depending on the complexity of the application, this may involve connecting several different circuits together in order to create a total circuit.

Once all components are connected, the user will need to test the system by applying power to it and ensuring everything works correctly. If there are any issues, it may be necessary to adjust the connections or components. Finally, the user should monitor the system periodically in order to ensure that everything is still functioning properly.

It’s important to remember that proper use of a Flyback Transformer requires knowledge of electrical theory and an understanding of basic circuit design principles. Inexperienced users should seek out professional guidance before attempting to install or use such a transformer.

Furthermore, the user should take steps to ensure their safety when working with high-voltage equipment. This includes wearing protective gear and isolating any exposed components from shock hazards. Additionally, they should make sure to securely attach all wires and other components before powering up the system. Taking these important safety precautions can help prevent damage or injury related to the use of the transformer.

FAQ

What is the difference between a flyback transformer and a regular transformer?

A flyback transformer is a special kind of step-up or step-down transformer used in power supplies. It has two distinct windings on the same core, enabling it to both store energy and transfer power between circuits from one AC cycle to the next. This allows it to provide high voltages for short bursts of time, while regular transformers are better suited to providing steady current over long periods. Flyback transformers are typically used to power television sets, computers, and other electronic devices.

How does a flyback transformer work?

A flyback transformer works by using the energy stored in its primary winding to create an impulse voltage in its secondary winding. This impulse voltage is then used to power the device. When the primary winding is energized, it creates a magnetic field that induces an electrical current in the secondary winding. This current is then used to power the device. The flyback transformer also has a diode connected across its primary and secondary windings which prevents the energy from flowing back into the source when the voltage drops.

What are some advantages of using a flyback transformer?

The main advantage of using a flyback transformer is that it can provide higher voltage and current than regular transformers for short periods. This makes them ideal for powering devices such as televisions, computers, and other electronic components that require sudden bursts of power. Another advantage is that they are relatively small compared to regular transformers, making them easier to install in tight spaces. Additionally, because they use a single core and winding, flyback transformers can be more cost-effective than regular transformers since they require fewer components.

Are there any drawbacks to using a flyback transformer?

The main drawback of using a flyback transformer is that it produces high-voltage spikes which can damage sensitive electronic components if not carefully regulated. Additionally, the diode across the primary and secondary winding can make these transformers less efficient than regular transformers. Finally, flyback transformers require more design time and expertise to be properly implemented, making them less suitable for use in mass-produced consumer electronics where cost is a major factor.

What safety considerations should be taken when using a flyback transformer?

When using a flyback transformer, it is important to ensure that the voltage and current ratings of the device are not exceeded. Additionally, proper insulation must be used when working with high-voltage components as there is a risk of electrocution. It is also important to avoid short circuits in the secondary winding, as this can cause a large current to flow which may damage the transformer. Finally, it is important to ensure that the flyback transformer is properly grounded and earthed to protect against electrical shocks.

Why is it called flyback?

The term “flyback” is derived from the action of the transformer winding itself. When the current in the primary winding is reversed, it causes a voltage spike which is then pushed back to the source. This “flying back” phenomenon gives rise to its name. Additionally, this same ‘flying backward’ effect produces high-voltage pulses that can be used to power electronic devices.

In more detail, the flyback transformer operates by temporarily storing energy in its magnetic field during the ‘flyback’ phase, and then releasing it when needed. This energy transfer process is crucial for various applications, such as CRT displays, where the flyback transformer helps generate the high voltages required to drive the electron beam. By harnessing the flyback effect, electronic devices can be efficiently powered with the aid of this ingenious magnetic phenomenon.

What other types of transformers are used in power supplies?

Other common types of transformers used in power supplies include center-tapped, full-wave bridge rectifiers, forward converters, and Buck-Boost converters. Center-tapped transformers convert AC current into DC current by using two taps on the secondary winding to create two separate AC voltages that are out of phase with each other. Full-wave bridge rectifiers also convert AC current into DC, but they use four diodes instead of one center tap. Forward converters convert higher input voltage into lower output voltage and can provide high power conversion efficiency. Buck-Boost converters operate similarly to forward converters, except they are able to both increase and decrease the output voltage depending on the input voltage.

What other applications do flyback transformers have?

Flyback transformers are also used in many consumer and industrial applications, such as welding equipment, lasers, microwave ovens, medical imaging equipment, and various types of power supplies. Additionally, they can be used for powering coils and motors in robotics, as well as actuating solenoids and relays. The high-voltage pulses produced by the flyback transformer also make it ideal for use in impulse welding systems, where an intense electric arc is required to fuse two pieces of metal together.

Flyback transformers are also used in many modern automotive applications such as electronic fuel injection, power window motors, airbag deployment systems, and anti-lock braking systems. By providing a safe and reliable way to convert AC current into DC current, flyback transformers are essential components in modern cars as they provide the necessary power for safety features such as airbags and ABS brakes.

Finally, flyback transformers can also be used in video game consoles, such as the Sony PlayStation and Microsoft Xbox, to provide the high voltage needed to power their graphics processors. These transformers are used in many other consumer electronics such as TVs, DVD players, and set-top boxes.

Is a flyback transformer AC or DC output?

A flyback transformer is an AC output device, meaning it produces alternating current. However, most applications require DC power so the output of a flyback transformer must be rectified (converted from AC to DC) in order for it to be used. This can be done using either a diode bridge or Schottky barrier diodes depending on the application. Rectified DC power is then used to power various electronic components that require constant voltage, such as microprocessors and motors.

How does a flyback transformer work?

A flyback transformer works by taking in AC current from an external source and using it to create a magnetic field in the transformer’s core. When the primary winding is reversed, the magnetic field collapses and generates a voltage spike which is then pushed back to the source. This “flyback” effect creates high-voltage pulses that can be used to power electronic devices. Additionally, the transformer may also include a diode across the primary and secondary winding in order to prevent current from flowing back into the primary circuit.

The flyback transformer is an efficient and cost-effective way to power various electronic devices. Its ability to produce high-voltage pulses with minimal energy loss makes it ideal for use in many applications such as CRTs, welding systems, robotics, fuel injection systems, and game consoles. Additionally, its relatively simple design allows for easy implementation and maintenance.

Conclusion Paragraph

In conclusion, a flyback transformer is a special type of transformer that is used for high-voltage pulse applications. It can be modified to fit various specifications, making it very versatile and reliable in multiple projects. Using a flyback transformer reduces the size and weight of a system while also increasing safety. Their unique design also makes them highly efficient and effective. When compared to other transformers such as step-down or autotransformers, flyback transformers provide the highest level of efficiency. Ultimately, they are a great choice when looking for reliable and efficient electrical solutions.

Useful Video: FLYBACK DC – DC Converter Theory And Example

References:

- https://www.coilcraft.com/en-us/edu/series/a-guide-to-flyback-transformers/

- https://www.electronicsforu.com/technology-trends/learn-electronics/flyback-transformer-basics

- https://www.sunpower-uk.com/glossary/what-is-a-flyback-converter/