Step into the world of MIM capacitors and prepare to be amazed by their boundless potential. These small yet mighty devices have become a critical component in countless electronic applications, revolutionizing the way of harness and store energy. Whether you’re a tech-savvy enthusiast or simply curious about the inner workings of modern technology, this comprehensive overview will unravel the mysteries of MIM capacitors, shedding light on their myriad benefits and fascinating range of applications. So, fasten your seatbelts and get ready for an exhilarating journey through the captivating realm of MIM capacitors!

Why are MIM Capacitors needed? And what for?

MIM capacitors are necessary for many modern electronic designs because they offer a number of advantages over traditional ceramic or film capacitors. MIM Capacitors provide very low equivalent series resistance (ESR) and higher frequency capability while offering significant miniaturization compared to other types of capacitors. This makes them ideal for use in high-frequency applications such as in RF filters, amplifiers, and oscillators.

MIM capacitors can also be used to provide decoupling for power converters, reduce noise in sensitive circuits, and even help protect circuit from voltage transients or surges. In addition to being smaller and more efficient than other types of capacitors, the use of MIM Capacitors can also result in cost savings due to reduced component count. As such, they have become an essential part of today’s modern electronics designs.

MIM capacitors can be used in almost any high-frequency application where size and efficiency are key concerns. This includes everything from mobile phones and computers to automotive systems, medical devices, and many other consumer electronics products. With their small size, superior performance, and cost savings, MIM capacitors are sure to be a key component of any modern electronic design.

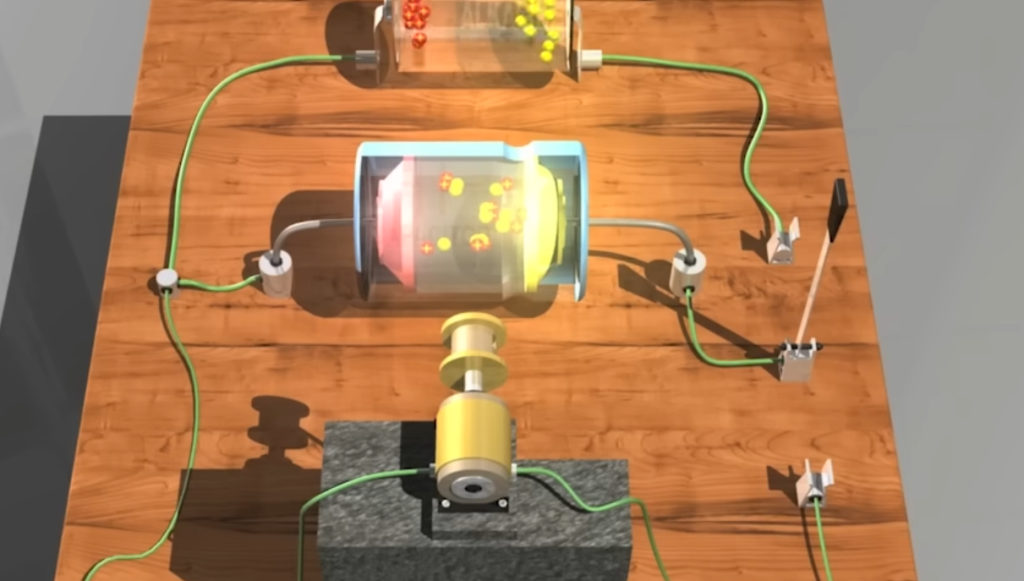

In addition to their use in high-frequency applications, MIM Capacitors can also be used for energy storage. This type of capacitor can store electrical energy in the form of an electric field between two conductive plates. This stored energy can then be used to power electronic devices, allowing them to work more efficiently and for longer periods. Energy storage capacitors are becoming increasingly popular in several applications, including solar energy systems, electric vehicles, and portable electronics.

MIM capacitors are an essential component of modern electronics designs. Their small size, superior performance, cost savings, and ability to store energy make them ideal for a wide variety of applications. As such, MIM capacitors are sure to be a key part of any modern electronic design [1].

How are MIM Capacitors Manufactured?

The MIM process yields highly reliable components that are capable of withstanding environmental extremes, such as temperature and vibration while maintaining their performance characteristics. This makes MIM capacitors ideal for use in a variety of applications where reliability is critical.

MIM Capacitors are also relatively simple to manufacture, making them cost-effective and widely available. This has enabled the widespread adoption of these components for many different types of electronic designs.

In addition to their manufacturing advantages, MIM Capacitors also offer high performance in a variety of applications. The combination of low ESR and high-frequency capability makes them ideal for RF filters, amplifiers, and oscillators. Their small size also makes them suitable for use in many types of portable electronic devices. Finally, their ability to store energy makes them an attractive choice for energy storage applications.

Structure of MIM capacitors

Element 1: Dielectric

MIM capacitors have an element called the dielectric that possesses a high dielectric constant. This is the material between the inner and outer plates of the capacitor and acts as a barrier against electric fields. The most common dielectrics used in MIM capacitors are ceramic, polymer, and tantalum. Each type has its unique advantages and disadvantages.

Element 2: Electrodes

MIM capacitors also require electrodes for the capacitor to work properly. The most common electrode materials used in MIM capacitors include aluminum, copper, gold, nickel, and titanium. Each material has its own set of properties that affect the performance of the capacitor. For example, gold is a good conductor of electricity while titanium is a better choice for high-temperature applications.

Element 3: Encapsulation

The third element of a MIM capacitor is the encapsulation. This material serves to protect the components from environmental elements such as moisture, dust, and heat. Common materials used for encapsulation include epoxy resin, polyimide resin, and silicone rubber. Depending on the application, different encapsulation materials will be used to ensure a reliable and long-lasting performance of the capacitor.

How does the MIM capacitor work?

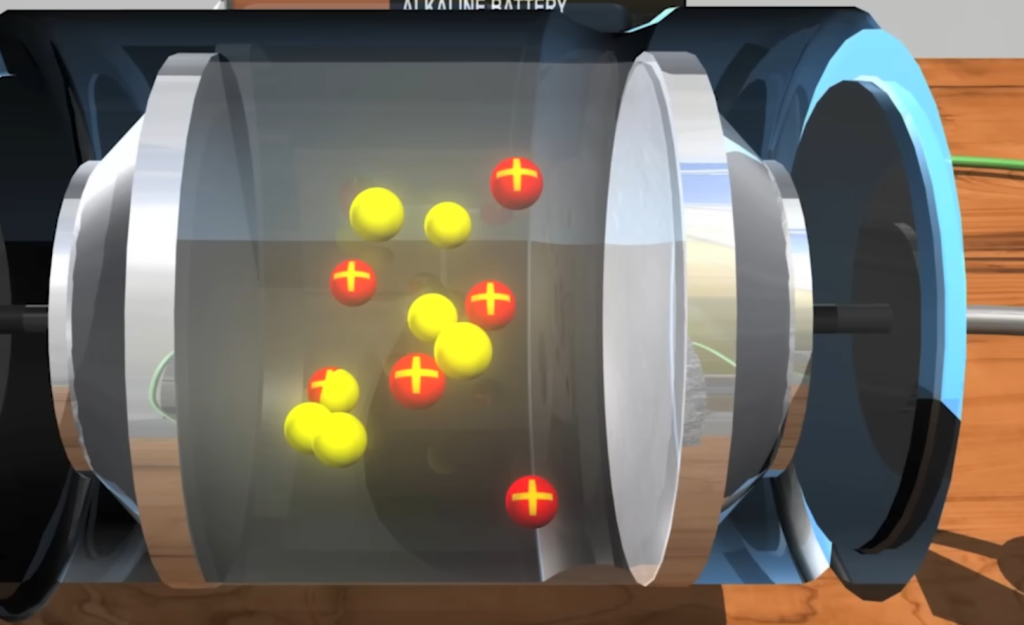

The MIM capacitor works by creating an electric field across two metal plates. This electric field is generated when a voltage is applied to the plates. The voltage causes electrons to move and accumulate on one plate while leaving the other plate with a negative charge due to electron deficiency. This creates an imbalance of charge that produces an electric field between the two plates, allowing for the storage of electric charge.

The MIM capacitor is advantageous because it has a low resistance, making it ideal for applications that require high-frequency operations and low power consumption. Additionally, its compact size makes it suitable for use in small electronic devices such as smartphones and wearables. It also has good temperature stability, making it reliable even under extreme temperatures.

Overall, the MIM capacitor is a reliable and efficient way to store electric charge, making it an excellent choice for many electronic devices. It is small in size, has a low resistance, and provides good temperature stability. With these qualities, the MIM capacitor can help power numerous applications that require high-frequency operations and low power consumption. Furthermore, its lengthy lifespan makes it an ideal choice for a wide range of applications.

Advantages and Disadvantages of the MIM Capacitor

The MIM capacitor has numerous advantages, including its low resistance, small size, and good temperature stability. Additionally, it is capable of handling high-frequency operations as well as low power consumption. These features make it a highly suitable option for many different applications.

On the other hand, there are some drawbacks to using MIM capacitors. Firstly, they tend to have lower capacitance values than other types of capacitors and require careful design considerations in order to keep them operating at peak performance. Secondly, due to their small size, they may not be able to meet certain voltage requirements and thus are not suitable for use in higher-voltage applications. Lastly, they may also be more expensive than other types of capacitors.

Despite the drawbacks, MIM capacitors can still prove to be an invaluable tool for engineers when used properly. By carefully considering their advantages and disadvantages before any design decision, it is possible to achieve great results using MIM capacitors. Keeping these considerations in mind, engineers can make informed decisions that will maximize the performance of their projects and ensure safe operation.

In addition, MIM capacitors can also be used in combination with other components to create larger circuits and systems. By combining several different components, it is possible to build complex machines such as computers or robots that use MIM capacitors as part of their design. By doing so, engineers can create highly efficient and reliable systems that are capable of performing a wide range of tasks.

Given the numerous advantages and disadvantages of using the MIM capacitor, it is important to carefully consider these factors before making any decisions. With careful research and analysis, engineers can make sure they are using the most suitable capacitor for their application and ensure that their designs will remain reliable for a long time. In any case, understanding all of the characteristics of the MIM capacitor is essential to make informed decisions. With this knowledge, engineers can be sure they are getting the best possible performance from their projects.

What is the Difference between MOM, MIM and MOS Capacitors?

MOM (Metal Oxide Metal) capacitors are made up of two metallic plates with an oxide dielectric between them and have the most stable electrical characteristics among all capacitors. MIM (Metal Insulator Metal) capacitors involve three layers; a metal plate, an insulation layer, and another metal plate on top. This type of capacitor has higher capacitance and lower leakage than MOM capacitors. Lastly, MOS (Metal Oxide Semiconductor) capacitors are ultra-miniature components that offer a very low profile compared to other types of capacitors, but with higher losses at high frequencies.

An important thing to consider when choosing between these three types of capacitors is their respective temperature coefficients, which can significantly affect the performance of the circuit if not taken into account. MOM capacitors have relatively low temperature coefficients while MIM and MOS capacitors have higher temperature coefficients and should be used in applications that may encounter extreme temperatures or high-frequency switching. In addition, MIM capacitors offer a higher tolerance than MOM and MOS types due to their three-layer structure. Finally, MOS capacitors are the most compact of the three types so they are often used in space-constrained applications.

Regardless of the type of capacitor chosen, it is important to understand how each type behaves under different conditions and choose the one that will best serve your needs. By considering all factors such as temperature coefficient, capacitance, size and tolerance, you can ensure that your circuit will operate as intended. Additionally, if special features such as high-frequency switching or noise suppression are required, then selecting the right type of capacitor is even more critical.

As technology continues to evolve and new types of capacitors come onto the market, it’s important to stay up-to-date on the different types and their performance characteristics to ensure that you select the right capacitor for your application needs. With the wide variety of capacitors available, it’s essential to understand how each type behaves under different environmental conditions so that you can make an informed decision when choosing a capacitor for your circuit.

Additionally, be sure to keep in mind any special requirements such as high-frequency switching or noise suppression when selecting a capacitor. By considering all the available options, you can make sure that your circuit will operate as intended and give you the best possible performance [2].

FAQ

What are MIM capacitors used for?

MiM capacitors are used in applications where high power and energy density are required. They can be used for energy storage, electrostatic discharge (ESD) protection, noise filtering, decoupling, and more. MIM capacitors have higher dielectric strength than other types of capacitors, making them suitable for use in high-voltage applications. Additionally, MiM capacitors are often used in applications where the need for high power and long life is paramount.

What benefits do MIM capacitors offer?

MIM capacitors offer numerous benefits over other types of capacitors. They feature an exceptionally high energy density, allowing them to store more energy than conventional capacitor types while occupying less space. Additionally, MiM capacitors have a high dielectric strength, making them highly reliable and suitable for use in high-voltage applications. These components are also highly robust with long lifespans and excellent temperature stability. Furthermore, MIM capacitors are often more cost-effective than other capacitor types due to their low manufacturing costs.

What is the difference between MIM and MLCC capacitors?

MIM (Metal-Insulator-Metal) and MLCC (Multilayer Ceramic Capacitor) are both types of capacitors. The main difference between the two is that MIM capacitors have higher dielectric strength than MLCCs, making them more suitable for use in high-voltage applications. Additionally, MIM capacitors have higher energy density and are more reliable than MLCCs. However, they are also typically more expensive due to their low manufacturing costs. On the other hand, MLCCs offer cheaper prices and better temperature stability but lack the high power capabilities of MiM capacitors.

Can MIM capacitors be used for RF applications?

Yes, MIM capacitors can be used in RF applications. They feature high dielectric strength and superior frequency response, making them ideal for use in RF circuits. Additionally, MiM capacitors have excellent temperature stability and low ESR (Equivalent Series Resistance). This makes them suitable for use in high-frequency applications where reliability is paramount. As such, these components are often used in wireless applications such as Wi-Fi and Bluetooth.

What is the difference between a MIM and MOM capacitor?

MIM (Metal-Insulator-Metal) and MOM (Metal-Oxide-Metal) are both types of capacitors. The main difference between the two is that MIM capacitors have higher dielectric strength than MOMs, making them more suitable for use in high-voltage applications. Additionally, MiM capacitors have higher energy density and are more reliable than MOMs. However, they are also typically more expensive due to their low manufacturing costs. On the other hand, MOM capacitors offer cheaper prices but lack the high power capabilities of MiM capacitors. Additionally, they have lower temperature stability and higher leakage currents compared to MiMs.

What is the shelf life of a MIM capacitor?

The shelf life of a MiM capacitor depends on several factors, including the type of insulating material used and the environmental conditions. Generally speaking, these components have an expected shelf life of 10 to 20 years when properly stored in a dry environment at moderate temperatures. However, it is important to note that high temperatures or humidity levels may reduce the lifespan of a MiM capacitor significantly. Therefore, it is important to store these components in an environment with controlled temperature and humidity.

What is MIM in semiconductors?

MIM (Metal-Insulator-Metal) is a type of capacitor architecture commonly used in semiconductor applications. It consists of two metal electrodes with an insulating layer in between them. This configuration allows for high capacitance and power density, making it suitable for use in applications where space and performance are key requirements. Additionally, MiM devices can handle higher voltage levels than other types of capacitors, making them suitable for use in high-voltage applications. As such, these components are often used in power management and energy storage circuits.

Are MIM capacitors RoHS compliant?

Yes, MIM capacitors are generally RoHS (Restriction of Hazardous Substances) compliant. This means that they do not contain any hazardous substances that could pose a risk to human health or the environment. As such, these components can be used in applications where RoHS compliance is required. Additionally, MiM capacitors are often UL (Underwriters Laboratories) certified for safety and reliability. This makes them suitable for use in consumer products and other applications where safety is essential.

Conclusion Paragraph

In conclusion, a MIM capacitor is a powerful and versatile tool for storing energy. It can be used in applications such as signal conditioning, power conversion, and electronic load switching. The advantages of using a MIM capacitor are its high capacitance, low equivalent series resistance (ESR), wide range of temperature operating ranges, low leakage current, and long life expectancy. Furthermore, the use of a metal-insulator-metal structure provides the added benefits of increased thermal management, increased power density, and improved reliability. For these reasons, MIM capacitors are becoming increasingly popular for use in a variety of different applications. This makes it an attractive option when choosing a capacitor for your next project or device.

Useful Video: How Capacitors Work

References:

- https://www.sciencedirect.com/topics/engineering/metal-insulator-metal

- https://www.utmel.com/blog/categories/capacitors/what-is-the-difference-between-mom-mim-and-mos-capacitors