Welcome to the electrifying world of precision resistors! Are you ready to embark on a journey of discovery and unravel the secrets behind these tiny but mighty components? Whether you’re a budding electronics enthusiast or a seasoned engineer looking to brush up on your knowledge, this comprehensive guide is here to demystify the perplexing realm of precision resistors. From their fundamental principles to their various types and applications, this guide will dive deep into the inner workings of these humble yet indispensable electronic devices. So, grab your soldering iron and start unlocking the mysteries of precision resistors!

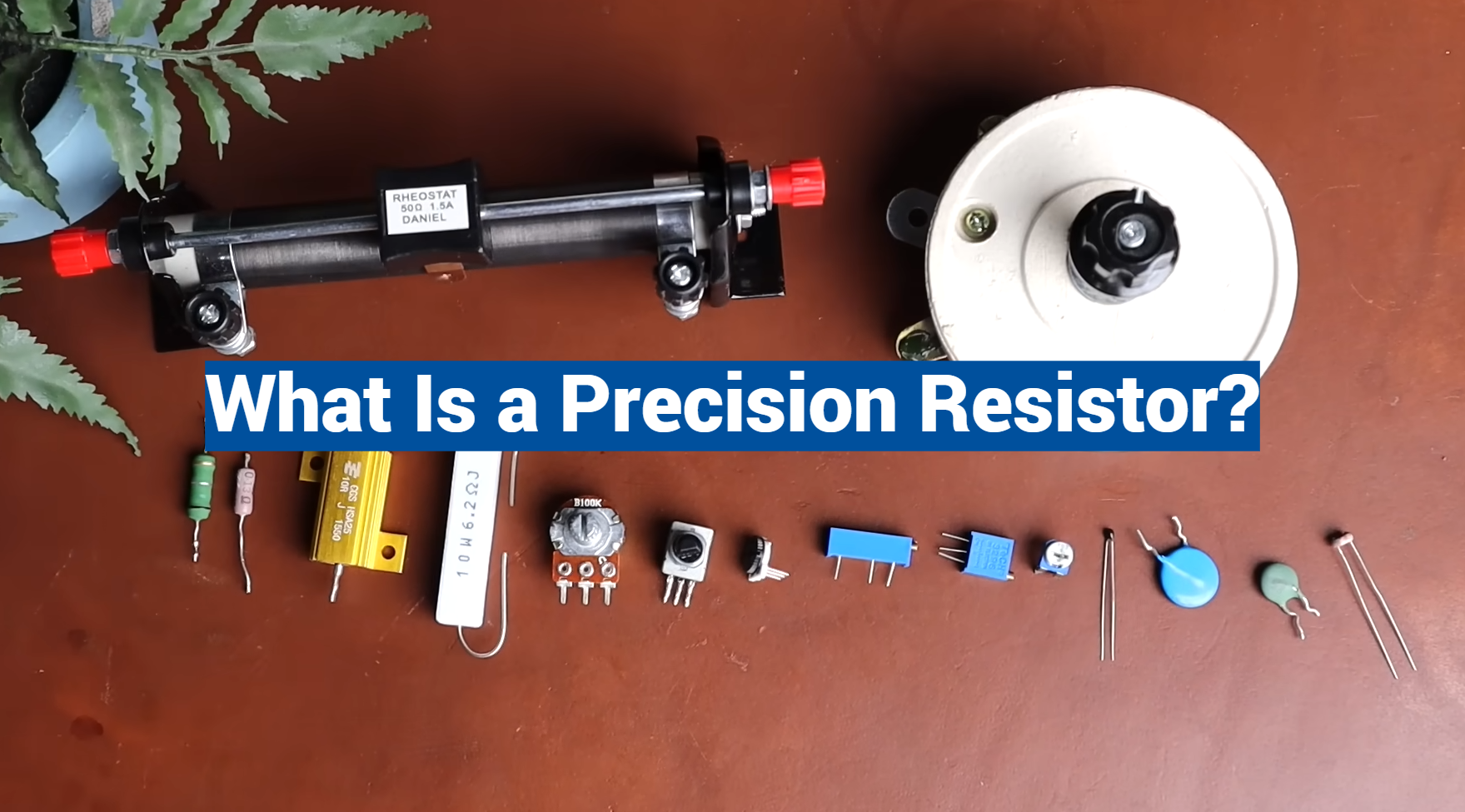

What is a Precision Resistor?

In addition to providing an accurate resistance value, precision resistors also provide a stable and consistent performance over time which is important for many electronic circuits. Precision resistors are designed to be used with other components such as capacitors or inductors to form complex networks that can regulate current flow and voltage levels. They can also be used in conjunction with other components to create filters and oscillators which are used in a variety of applications such as radio receivers or sound amplifiers.

When choosing precision resistors for an application, it is important to consider the operating temperature range, power rating, and tolerance values that are required for the desired performance. The most common types of precision resistors are metal film, carbon film, and wire-wound. Each type has its own advantages and disadvantages when compared to the other types.

The use of precision resistors is essential in many electronic circuits as they provide a stable resistance value with minimal drift over time. This makes them ideal for applications where accuracy and consistency are important such as measuring instruments or medical equipment. By using precision resistors, designers can ensure that their circuits are functioning correctly and efficiently. Additionally, they can also be used to provide additional protection against voltage or current overloads which can damage components in the circuit [1].

Differences between Precision Resistors and Ordinary Resistors

Difference in Material Performance

Precision resistors are meticulously crafted using materials that possess exceptional temperature stability and minimal current noise. These characteristics make them exceptionally well-suited for applications necessitating precise measurements, such as instrumentation or high-end audio equipment.

On the other hand, while ordinary resistors may offer a more budget-friendly option, they often exhibit greater performance variations when subjected to temperature fluctuations or electrical loads. This underscores the significance of opting for precision resistors in scenarios where utmost accuracy and consistency are paramount.

Substantial Difference in Tolerances

Another major difference between precision resistors and ordinary resistors is the level of tolerances. Standard resistors are usually manufactured with a 10% tolerance, meaning they can deviate as much as 10% from their nominal value. On the other hand, precision resistors are typically made with tighter tolerances of 1%, 0.1%, or even 0.01%.

This makes precision resistors an ideal choice for applications that require extremely accurate, stable values. Moreover, this degree of tolerance also helps to reduce the risk of inconsistencies and errors resulting from variations in resistor value due to temperature or load changes.

Difference in Cost

There is a substantial cost difference between precision resistors and standard resistors. Generally speaking, precision resistors are much more expensive due to the higher quality material used in their manufacture and their tighter tolerances. This often serves as a deterrent to designers who may be working on projects with tight budgets, making ordinary resistors a more attractive option.

It should be noted, however, that using precision resistors can ultimately save money in the long run. This is because they are more reliable and accurate, meaning fewer replacements and repairs are needed. Additionally, greater consistency in performance can lead to higher efficiency of equipment or systems.

Difference in Digital Models

Another key distinction between precision resistors and ordinary resistors is the availability of digital models. Many precision resistor manufacturers offer digital models with more complex features that can be programmed to adapt to different conditions or environments. This makes them especially useful for automated systems or in applications where components may need to be adjusted quickly and easily. By contrast, standard resistors typically do not have these features, making them more suitable for simpler applications.

Ultimately, the choice between a precision resistor and an ordinary resistor will depend on the specific requirements and budget of a given project. In situations where accuracy and stability are paramount, precision resistors are often the best option. However, in cases where cost is a major factor, ordinary resistors may provide a more practical solution.

Difference in Color Wheel Reading

Precision resistors are also distinguished by the way they can be read on a color wheel. Precision resistors typically feature more colors than standard ones, making them easier to identify and interpret. This makes it easier for engineers and technicians to determine their nominal values with greater accuracy and precision.

By contrast, ordinary resistors may only feature three or four colors, making it more difficult to accurately estimate their values. As such, precision resistors are often the preferred choice when measuring delicate electronic components or in other situations where maximum accuracy is essential.

In addition to these differences, precision resistors may also be able to handle higher voltages and currents than ordinary ones. This is especially beneficial when dealing with high-powered electronics or machinery, as the resistors must be able to withstand tougher conditions. All of these factors demonstrate why it is important to evaluate a project’s requirements before selecting either precision or ordinary resistors.

Difference in Application

The application of precision resistors and ordinary resistors can also vary greatly. Precision resistors are often used in sensitive equipment that requires accurate measurements, such as instrumentation or medical imaging. On the other hand, ordinary resistors may be employed in simple circuits where a lesser degree of accuracy is acceptable. In either case, it is important to select the appropriate type of resistor for the application in order to ensure optimal performance.

It is also important to consider the environment in which each type of resistor will be used. Precision resistors are often best suited for indoor applications, due to their better temperature stability and greater resistance to environmental fluctuations. On the other hand, ordinary resistors may be more suitable for outdoor use as they can handle harsher conditions more effectively [2].

Classification of Precision Resistors

Metal Film Precision Resistors

Metal film precision resistors are the most common type of resistor. They are made of metal and typically contain a ceramic substrate, which provides insulation from electrical noise. Metal film resistors have low tolerance and good stability over temperature ranges. They are also resistant to corrosion and vibration, making them ideal for use in high-end industrial applications such as motors and robotics.

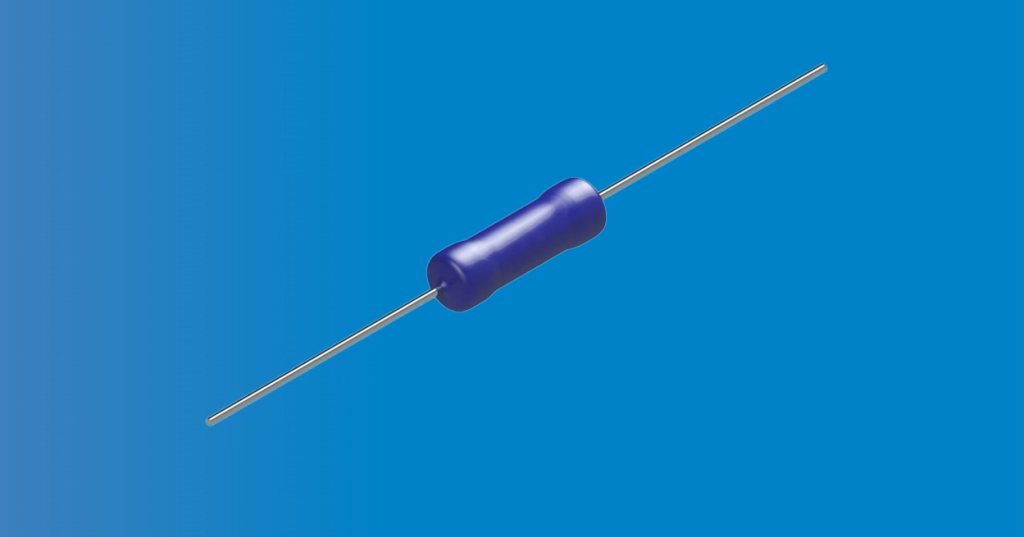

Wire-wound Precision Resistors

Wire-wound precision resistors are made of metal wire that is wrapped around a ceramic core, providing additional insulation against electrical noise. Wire-wound resistors have higher tolerances than metal film resistors but provide less stability over temperature ranges. They are also not as resistant to corrosion or vibration, making them more suitable for applications in which these factors do not need to be considered.

Carbon Precision Resistors

Carbon precision resistors are composed of carbon, which provides higher tolerances than metal film or wire-wound resistors. Carbon precision resistors perform best in low-noise applications, as they provide the highest level of insulation against electrical noise. They also offer good stability over temperature ranges and corrosion resistance, making them suitable for many different types of applications. Additionally, carbon precision resistors can be used in high-end industrial applications due to their ability to dissipate heat more quickly than other types of resistors.

Metal Foil Precision Resistors

Metal foil precision resistors are made of thin layers of metal foil, typically aluminum or copper. Metal foil resistors have the highest tolerance of all resistor types, making them ideal for very precise applications. They also provide good stability over temperature ranges and resistance to corrosion and vibration, making them suitable for use in high-end industrial applications. However, metal foil resistors do not provide the same level of insulation against electrical noise as other types of resistors.

Main Parameters of Precision Resistors

Accuracy

Accuracy is one of the main parameters to consider before selecting a precision resistor. The accuracy describes how close the value of the resistance will match its actual or nominal value. This can be expressed in terms of a tolerance percentage, such as 1%, 2%, 5%, and 10%. The lower this percentage is, the better the accuracy of the resistor.

Temperature Excursion

Temperature excursion is another important parameter to consider when selecting a precision resistor. This parameter indicates how much the resistance will change due to temperature changes. It is expressed as a percentage of the maximum rated power and is typically in the range of 0.01%/°C to 0.1%/°C for precision resistors. The lower this value, the less the resistance will change due to temperature fluctuations.

Load Life Characteristics

Load life characteristics describe how the resistor will behave when subjected to long-term use. The main parameter to consider is the rated power, which describes the amount of power that can be safely applied to a resistor without causing any damage. Other parameters such as operating temperature range, insulation resistance, and soldering heat resistance should also be taken into account when selecting a precision resistor.

Noise

The noise generated by a precision resistor is also an important parameter to consider. This can be expressed in terms of peak-to-peak voltage or current noise, which describes the amount of electrical noise that will be produced when the resistor is operating at its rated power. The lower this value, the better the performance of the resistor. Additionally, the temperature coefficient of noise should also be taken into account to determine how much the noise level will vary with temperature.

Power Rating

The power rating of a precision resistor is also an important factor when selecting one. It indicates how much power the resistor can safely dissipate without damage or destruction. The higher the power rating, the greater the amount of current that can be safely applied to it without causing any damage. Generally speaking, the power rating should be chosen such that it is higher than the maximum anticipated current load. This will ensure that the resistor is not overloaded and can withstand the expected amount of current flow.

Shelf Life

The shelf life of a precision resistor is also an important parameter to consider. This indicates how long the device can be stored before it begins to degrade and loses its accuracy. Generally speaking, precision resistors should have a shelf life of at least 5 years if they are properly stored and handled. Additionally, the manufacturer’s instructions should be followed closely when storing these components to ensure the best possible performance [3].

Pros and Cons of Mainstream Precision Resistor Technologies

Mainstream precision resistor technologies have various advantages and disadvantages. On the plus side, they offer a wide range of resistance values with high accuracy and reliability. Furthermore, these components are widely available in both commercial and military-grade versions, allowing them to be used for a variety of applications.

Another advantage is that mainstream resistor technologies are relatively inexpensive when compared to other types of resistors. Additionally, they are highly resistant to vibration and temperature variations, making them suitable for use in applications where such conditions may be present.

On the downside, mainstream resistor technologies are not always able to meet more specialized requirements. For example, if a particular resistance value is needed that is not available in a commercial or military-grade version, it may be necessary to select a resistor from another type of technology. Additionally, they are not always the best choice for extreme environments that require extra protection against shock, vibration, or temperature fluctuations.

Finally, mainstream resistor technologies can suffer from aging effects over time if they are used in high-current applications. This can lead to drift and accuracy loss, which must be taken into account when selecting a resistor for a particular application. To mitigate this, regular maintenance and periodic replacement of resistors may be necessary.

Overall, mainstream precision resistor technologies are generally reliable and cost-effective components that can be used in a variety of applications. As such, they remain popular among engineers and electronics hobbyists alike. However, users should keep in mind the potential downsides listed above when selecting a resistor for their project. With proper planning and maintenance, these components can be a great choice for many applications.

FAQ

Where is the precision resistor used?

Precision resistors are used in a wide variety of applications, including radio and television receivers, high-frequency circuits, audio amplifiers, power supplies, and digital logic circuits. They can also be used to measure voltage levels in capacitors or other components that contain an electrical charge. Additionally, they help regulate current flow in electronic devices and control the speed of motors. Finally, precision resistors are also used to measure temperature, pressure, and other physical properties of objects.

What is the tolerance of a precision resistor?

Tolerance is an important factor when selecting a precision resistor as it determines how accurately the desired resistance value can be achieved in practice. Generally, most precision resistors have tolerances in the range of 0.1-0.5%. These tolerances are expressed as a percentage of the nominal value, with higher numbers representing better accuracy. For example, a resistor with a tolerance of 0.25% will have an actual resistance value that is within 0.25% of the desired value.

What materials are used to make precision resistors?

Precision resistors are typically made of a variety of metals, including copper, nickel, silver, and gold. These materials are combined in specific ratios to create the desired resistance value. Additionally, they can be coated with insulating or ceramic materials that protect them from damage due to heat or humidity. Finally, precision resistors can also be constructed using thin film technology for superior accuracy and stability.

How does a precision resistor work?

A precision resistor works by controlling the flow of electrical current in an electronic circuit. It does this by providing a specific amount of resistance to the current, which can be adjusted depending on the desired results. The resistance value is determined by the material it is made from and its physical size. When the voltage across the resistor is increased, the amount of current that can flow through it decreases. This allows precision resistors to be used for a variety of purposes, from regulating voltages to controlling motor speeds.

What is a precision resistor made of?

Precision resistors are usually made of combinations of metals such as copper, nickel, silver and gold. These materials are combined in specific ratios to produce the desired resistance value. Additionally, precision resistors can also include ceramic or insulating coatings for added protection from heat and humidity. Finally, thin film technology is often used for constructing high-precision resistors due to its accuracy and stability.

What are the benefits of using a precision resistor?

The primary benefit of using a precision resistor is that it allows for precise control over electrical current in an electronic circuit. The resistance value can be precisely adjusted depending on the desired results, allowing for accurate voltage regulation or motor speed control. Additionally, precision resistors tend to be more stable than other types of resistors, making them better suited for long-term applications. Finally, they are also much smaller in size than regular resistors, which makes them ideal for use in space-constrained devices.

Are there any disadvantages to using a precision resistor?

Despite their many advantages, precision resistors can be quite expensive compared to other types of resistors. Additionally, they may not be suitable for applications that require extreme power handling capabilities due to their small size. Finally, since precision resistors are typically manufactured using thin film technology, they tend to have longer lead times and higher production costs when compared to regular resistors.

What is the maximum wattage rating for a precision resistor?

The maximum wattage rating for precision resistors can vary depending on their size and the materials they are made from. Generally, larger precision resistors can handle higher wattages than smaller ones, with some being able to withstand up to 10 watts of power. However, it is important to note that this value will also depend on the ambient temperature in which the resistor is being used, as higher temperatures can cause it to overheat. Be sure to check the manufacturer’s specifications for your particular resistor before installing it to avoid any potential problems.

How accurate are precision resistors?

Precision resistors are typically very accurate, with most having tolerances in the range of 0.1-0.5%. This means that their actual resistance value will be within 0.1-0.5% of the nominal value, making them ideal for applications where accuracy is paramount. Additionally, precision resistors tend to have good temperature stability and low noise levels, making them even more reliable for critical applications.

How long do precision resistors last?

The lifespan of a precision resistor will vary depending on its design and the environment it is used. Generally speaking, most types of precision resistors can last for many years with proper care and maintenance. High-quality resistors are designed to withstand extreme temperatures and other environmental conditions, making them suitable for long-term applications. Additionally, the use of ceramic or insulating coatings helps protect the resistor from damage due to heat or humidity.

What is a semi-precision resistor?

A semi-precision resistor is a type of resistor that offers improved accuracy compared to regular resistors, but not as much as a precision resistor. Generally, these components have tolerances in the range of 1%-5%, making them suitable for applications where accuracy needs to be maintained over time. Additionally, semi-precision resistors tend to be less expensive than their precision counterparts, making them a more cost-effective option in some cases.

How does temperature affect precision resistors?

Temperature can have a significant effect on the performance of precision resistors. In general, as the ambient temperature increases, the resistance value of the resistor will decrease. This can cause incorrect voltage regulation or motor speed control if not accounted for. Additionally, extreme temperatures can cause the resistor to overheat and fail prematurely if it is not designed for such conditions. It is important to check the manufacturer’s specifications for your particular resistor before installing it in an application.

Why is thin film technology used for precision resistors?

Thin film technology is often used for precision resistors because it offers superior accuracy and stability compared to other manufacturing methods. The thin layers of materials used in the construction process can be precisely controlled, allowing for the production of components with extremely tight tolerances. Additionally, these components are also much smaller in size than traditional resistors, making them ideal for space-constrained devices. Finally, due to the high levels of accuracy and stability achieved with thin film technology, precision resistors are often well-suited for applications such as voltage regulation or motor speed control.

Conclusion Paragraph

So, precision resistor networks are an integral part of modern electronic circuitry and have become increasingly popular in recent years due to their reliability, accuracy, and low cost. With continuing advances in technology, resistor networks continue to evolve and be used in a variety of different applications. As technology progresses, the advancements in engineering will help enable further improvements in precision resistor networks and other related components, furthering their use in both analog and digital circuits.

Useful Video: Precision Resistors Explained: Ultimate Guide to Features and Applications

References:

- https://medium.com/@joanneterrymri/precision-resistor-what-you-need-to-know-3d3fca2cb528

- https://www.utmel.com/blog/categories/resistor/beginners-guide-to-precision-resistors

- https://blog.techdesign.com/4-specifications-that-determine-resistor-selection/